How Can We Help?

Search for answers or browse our knowledge base.

-

Retro C

-

-

- Articles coming soon

-

- Configuring the Touchscreen Computer's "Power-On"

- How to replace micro USB on the display computers

- How to Replace the Retro C's Computer

- How to replace the USB hard drive on the touch screen computer

- How To: Transfer Files to the Retro C

- New computer set bios power on

- Old computer set bios to power on

- TouchScreen Flip / Mirror Issue

-

-

-

- Angle (Arch) Movements - Overview

- Angle Chains - Proper Chain Tension

- Angle movements over run when going to position.

- Diagnosing Unknown Noises Coming from Blade Motor

- Pivot Point Check

- Power or Wiring Troubleshooting for Angle Motors or VFDs

- Replacing an Angle Encoder

- Stuck Angle or Centerline - How to Recover & Recalibrate

-

- Centerline (Vertical) Movements - Overview

- Checking the Centerline Maximum & Minimum (Max & Min) Height Setting

- How to set the "Minimum" position for Blade #5

- How to Tighten the Centerline Slides

- How To: Calibrate Centerline 1-5

- How To: Calibrate Centerline 1-5 (Advanced)

- How To: Tension The Centerline Chains

- Replacing a Centerline Encoder

- Replacing a Centerline Gearbox

- Stuck Angle or Centerline - How to Recover & Recalibrate

-

-

-

- Common Retro C issues and solutions

- Countdown Timer / E-Stop Troubleshooting

- Scrap Belt or Scrap Incline VFD Disconnected: Troubleshooting

- Stuck Angle or Centerline - How to Recover & Recalibrate

- TouchScreen Flip / Mirror Issue

- Troubleshooting: Encoder Unplugged Error

- Troubleshooting: The Stationary or Carriage Side Horizontals Won't Move Anymore

-

-

Linear Pickline

-

Plant One Projection

-

SmartConveyor

-

Sticker Printer

< All Topics

Print

Replacing a Horizontal Encoder

UpdatedOctober 20, 2024

Tools Needed: Phillips Head Screwdriver, 3/8” Socket Wrench

Time: 10 min

People: 1

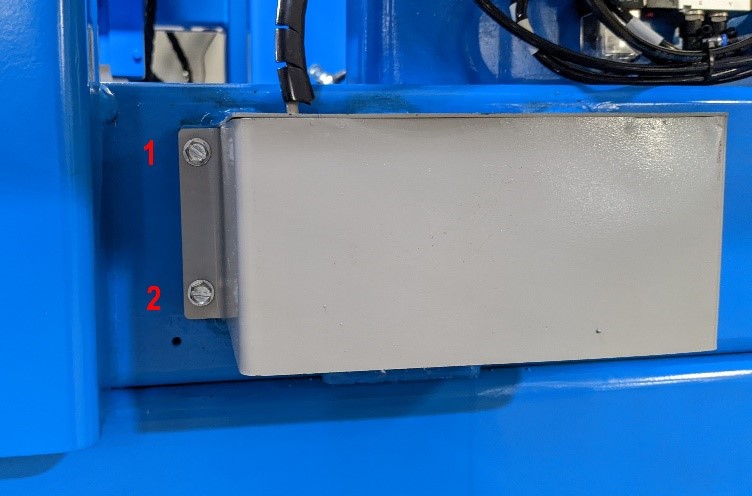

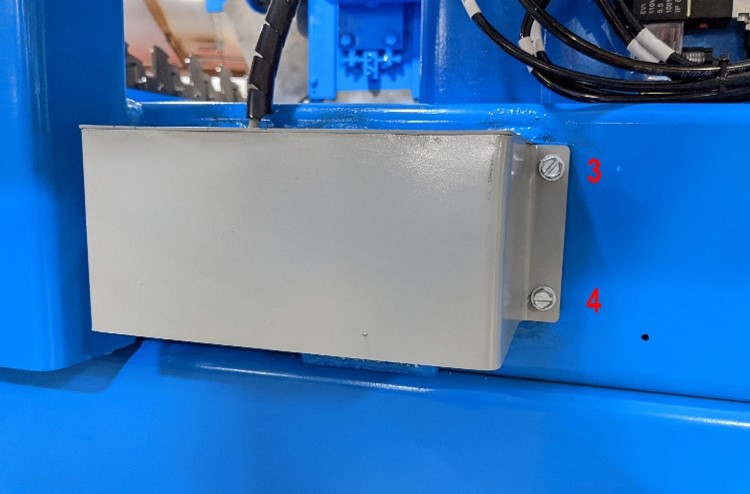

Step 1: Locate the rotary encoder on the rear of the saw that you need to replace. NOTE: There are two encoders, one for each side (even though only one is shown here). You will need to remove the cover to access and replace the encoder.

TIP: Many of the encoders on the Retro C component saw are covered by gray covers.

Step 2: Remove the (4) bolts using a 3/8” socket wrench.

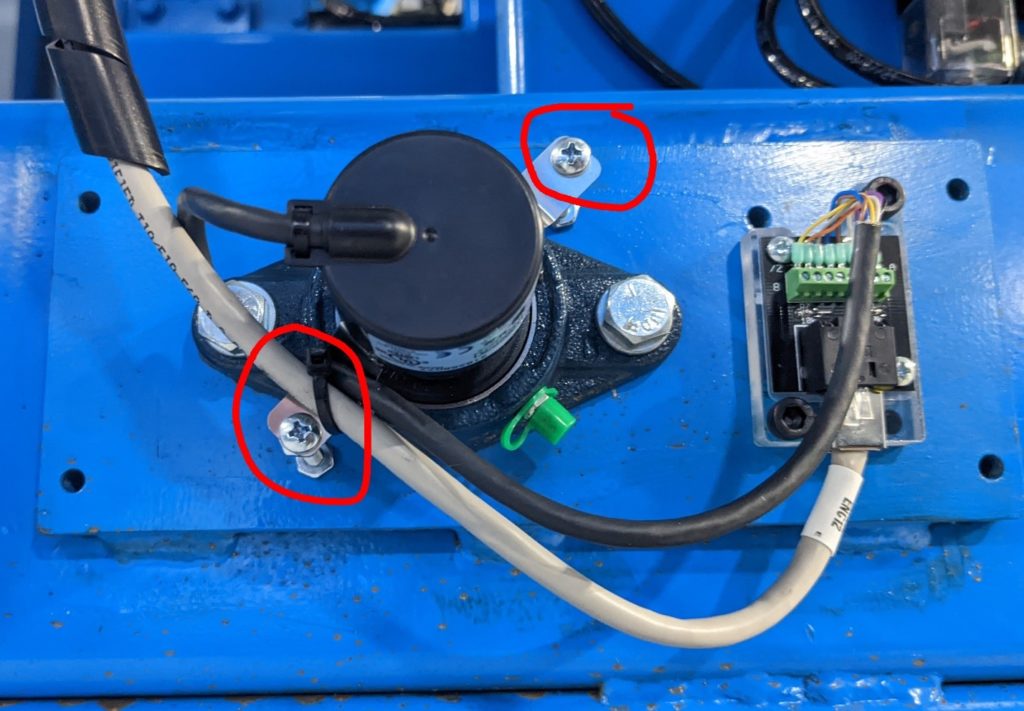

Step 3:

- Remove the zip tie, making sure NOT to cut the wires.

- Use a Phillips head screwdriver to remove the two screws holding the rotary encoder in place.

- Remove the rotary encoder that has stopped working properly.

- Measure the length of the wire and cut it to match the wiring block

- Wire encoder to the encoder block. Wiring Block instructions

- Re attach encoder as it was removed.

- Re-attach screws and zip tie wires to the unit as shown above.

- Replace the gray cover using the original bolts.

All Done!

Table of Contents