Search for answers or browse our knowledge base.

Replacing a Blade Motor

To replace a blade motor there are 9 steps

- Power down the entire saw

- Remove the saw blade

- Unwire the (2) airlines and unwire the power cables

- Remove the brake assembly

- Using a hoist or forklift as a hoist remove the old blade motor

- Attach the new blade motor

- Re-attach the brake assembly

- Re-wire the power cables and replace the (2) airlines

- Attach the saw blade

Step 1: Power Down the Saw by Disengaging the Main Breaker

Turn off the power to the saw by throwing the main breaker switch on the stationary side

Step 2: Remove the Saw Blade

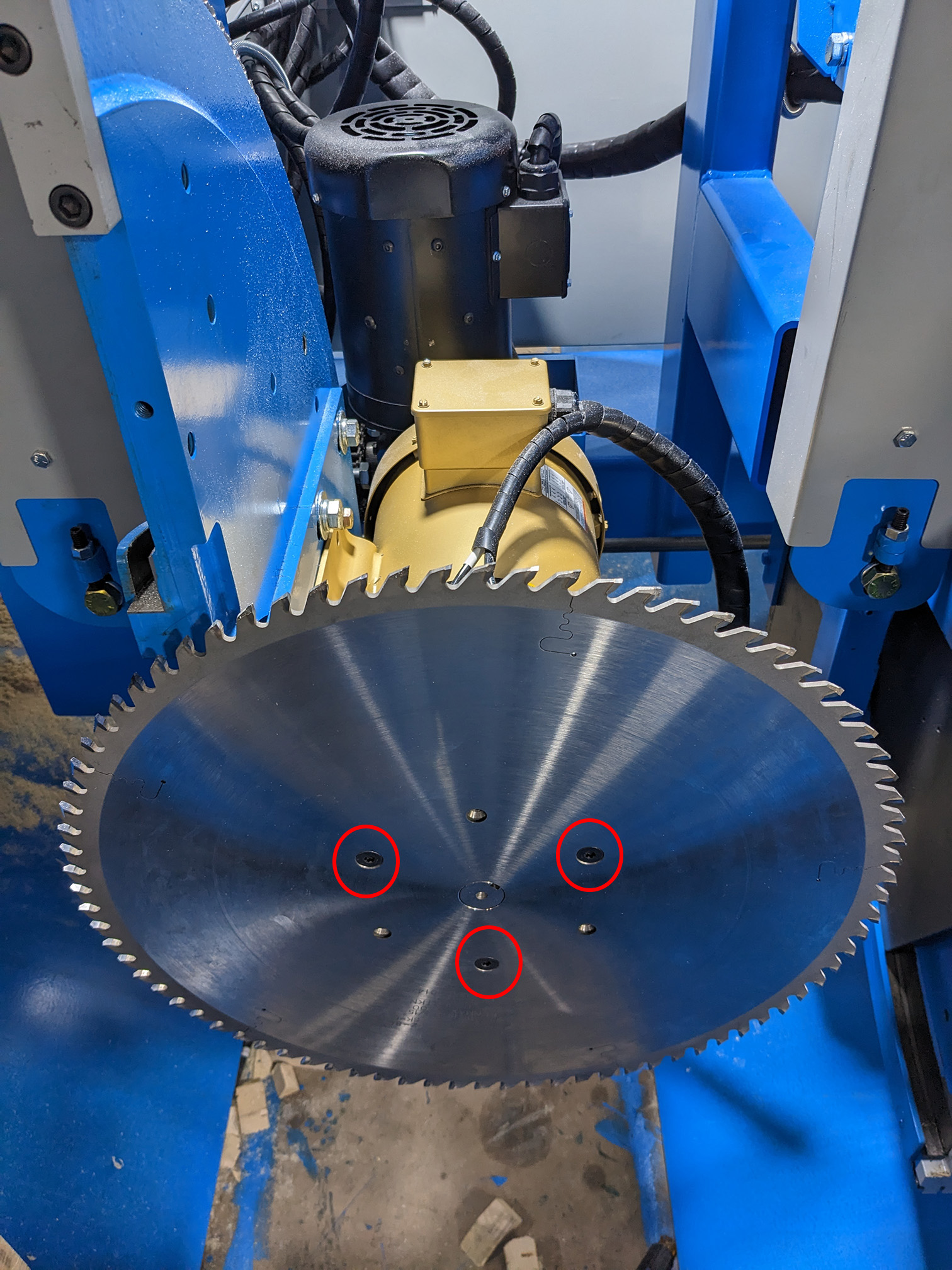

For this step, you will need a Torq wrench or ratchet and a T40 TORX bit. Simply remove the 3 (blade #5 has qty 6) screws attaching the blade to the motor.

Step 3: Unwire both airlines and disconnect/unwire the power cables

For this step, I recommend that you write down/take note of which airline goes to the left/right connectors.

- Remove the two air hoses.

- Remove the four screws on the top of the electrical box on the motor.

- Disconnect the wires inside, and pull the electrical cord free from the motor.

Step 4: Remove the Brake Assembly

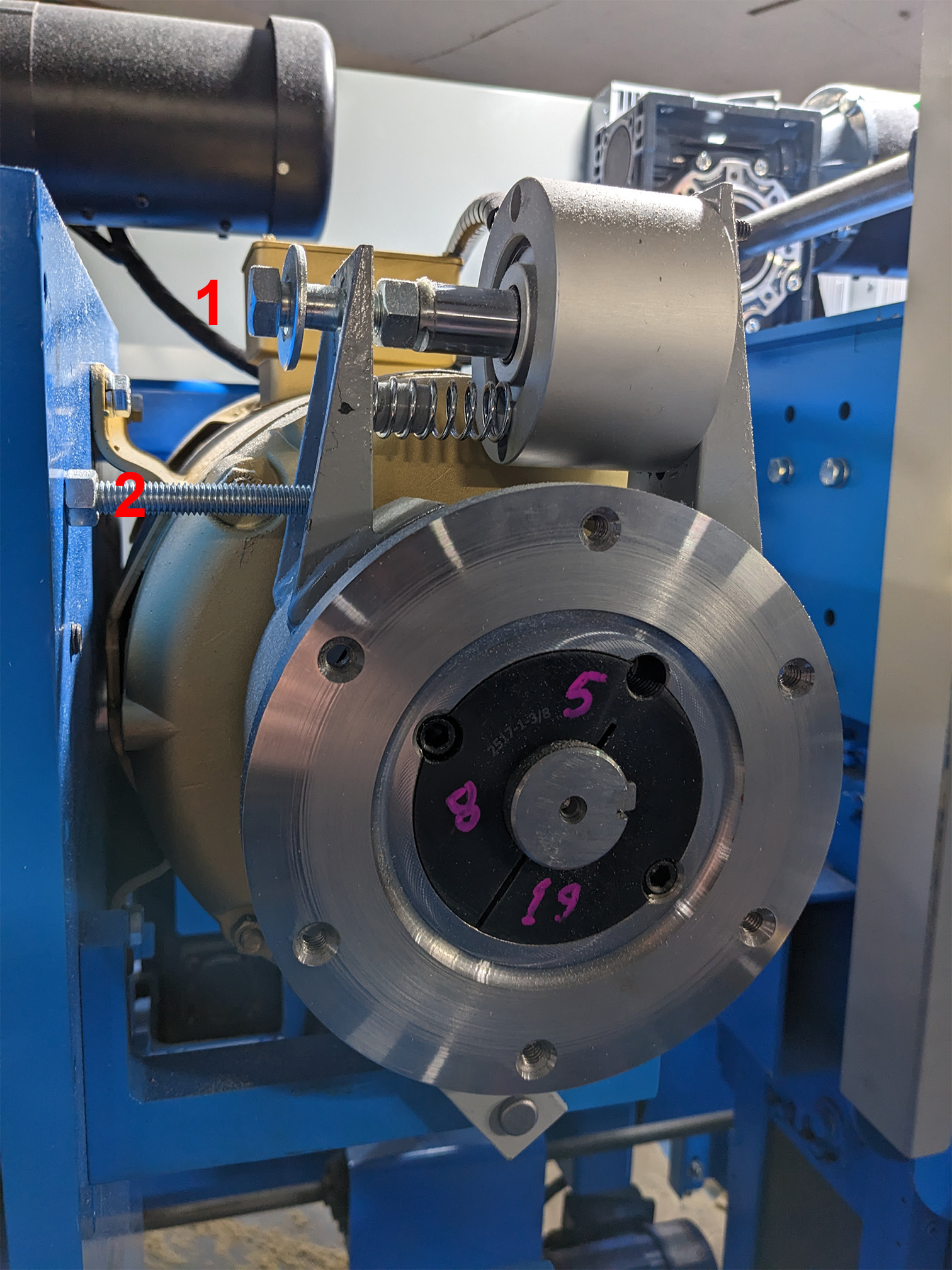

To remove the assembly, start by removing bolts 1 & 2

Then underneath the brake, you will find 2 set screws, use Allen wrenches to loosen those.

Once set screw #2 is loose you will be able to pull the pin out and the entire assembly should be able to be removed.

Step 5: Remove the Motor

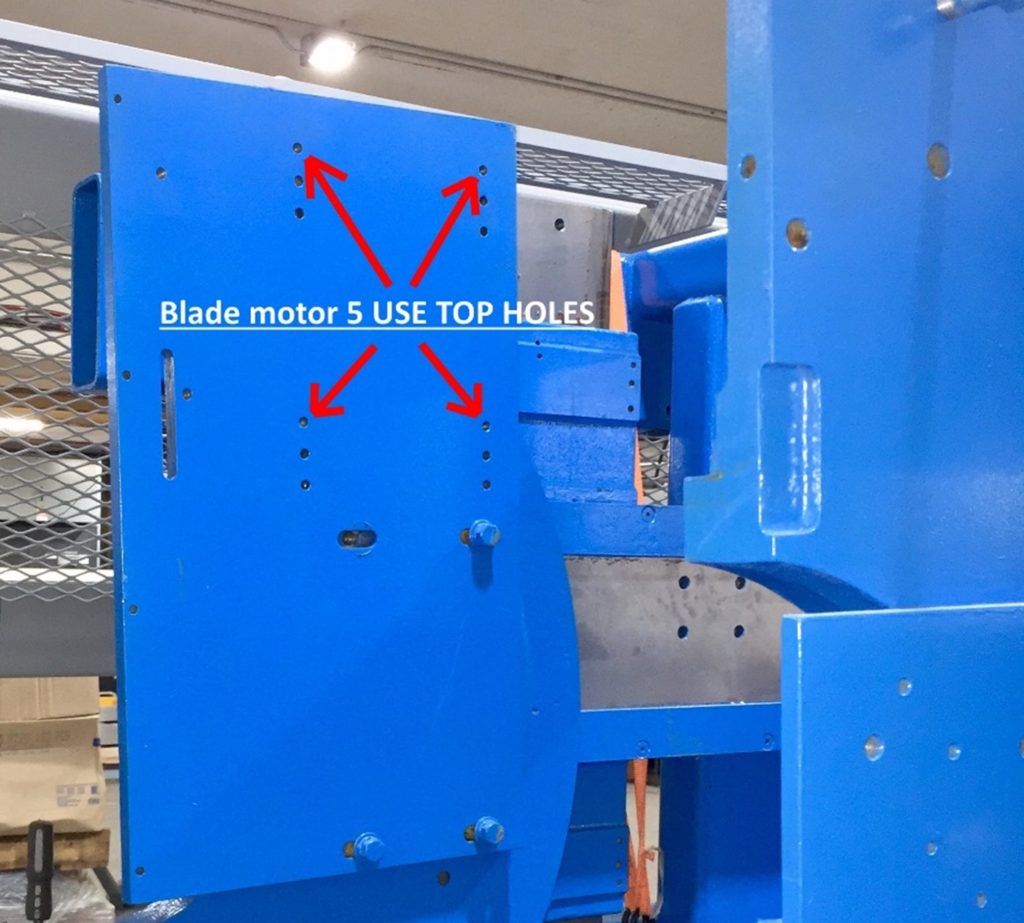

You are now ready to remove the motor, to remove we highly recommend that you use a winch or hoist of some sort to help lift the motors since they are heavy (motors 1-4 weigh 100lbs, motor 5 weighs 150lbs). Wrap your rope around the motor the way pictured below or loop the rope around both ends (either way works). Remove the 4 bolts and you are half done with the motor swap.

Step 6: Replace the Motor

Using the winch, lift the new motor into place and bolt it back into place.

Step 7: Re-attach the Brake Assembly

Reverse the process that you went through in step #4

Step 8: Re-attach the Air Hoses and re-wire Electrical Box

Hopefully, you wrote down which cable goes to which of the two connectors. If you never wrote it down and don’t remember you can guess and then use the lock/unlock “Blade Brakes” button in the software to toggle their state and see if you guessed right or not.

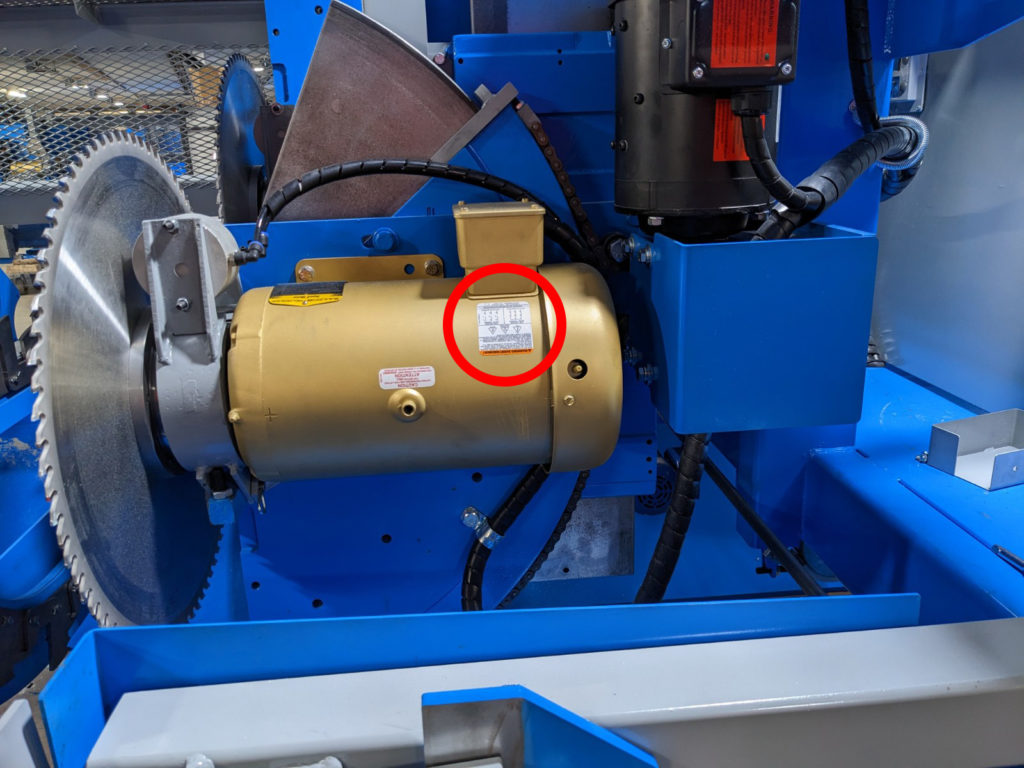

If you have any questions about which wires to connect in the electrical box, we use the “Low Voltage” wiring scheme that is printed on a sticker on the side of the motor.

Wire wires (9 & 3), (8 & 2), (7 & 1) as well as (6, 5 & 4) each together using the 4 wire nuts.

Step 9: Re-attach the blade

Use the T40 TORX bit and a Torque wrench to torque the screws holding the blade to 20 ft-lbs.