Search for answers or browse our knowledge base.

Stuck Angle or Centerline – How to Recover & Recalibrate

At times the Centerline and or Angle motors will stall when trying to move to position. This typically occurs due to one or more of these reasons.

- Debris has gotten into the chain that drives these movements.

- Debris has gotten into the slide on either the angle or the centerline which can cause it to stall.

- The Angle or Centerline is out of calibration and impacted the end stop at full speed and it will not back off now because it is jammed.

If the Centerline has Stalled because it has hit an endstop and become jammed up and is unable to move follow these steps.

Overview

- STEP 1: First first thing to try is to enter the repair tab and settings in the software for the affected Angle/Centerline. Use the arrow and stop keys to try manually freeing the movement via the software.

- STEP 2: If that doesn’t work the fan cover may need to be removed from the motor in order to clear the debris or free it from the end stop. Once the movement can move freely again and if it was due to debris then lubricate the slide and move it back and forth a few times in order to remove further debris.

- STEP 3: If the stall was due to an impact of the end stop, recalibration is required. If the head stalls or jams regularly the encoder likely needs to be checked for tightness or failure at which point replacing the encoder is highly suggested.

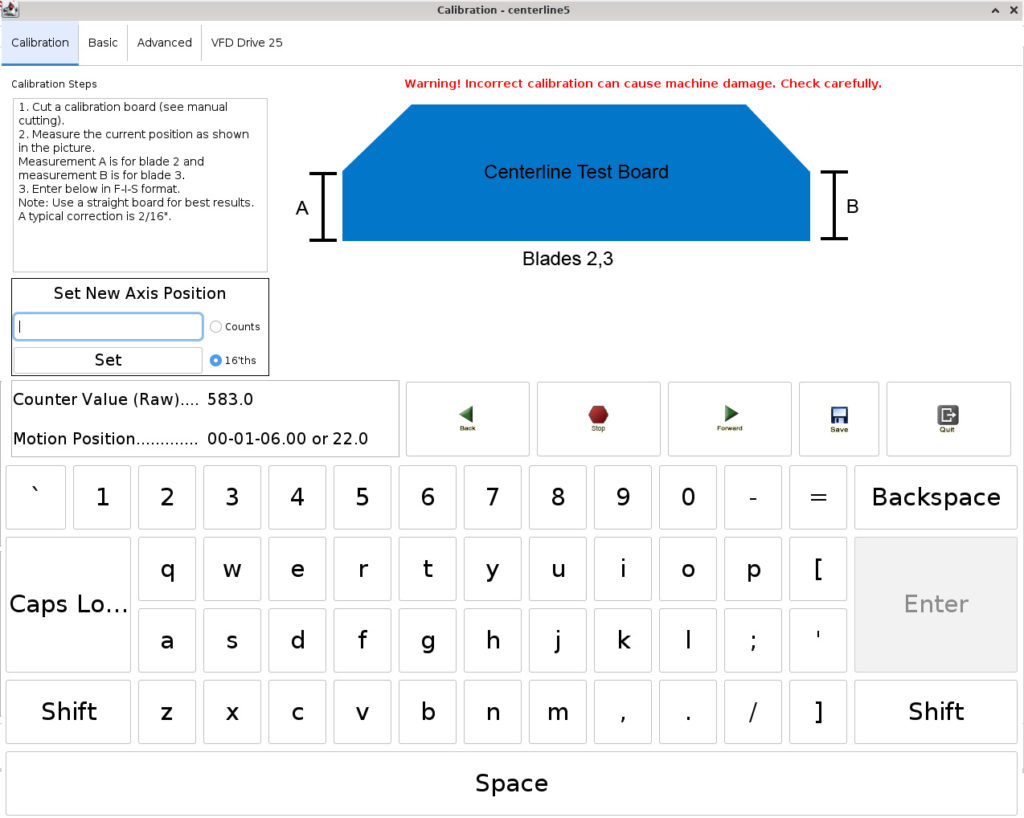

Step 1: Move the Head using the motor’s maximum power output in the “Calibration” window.

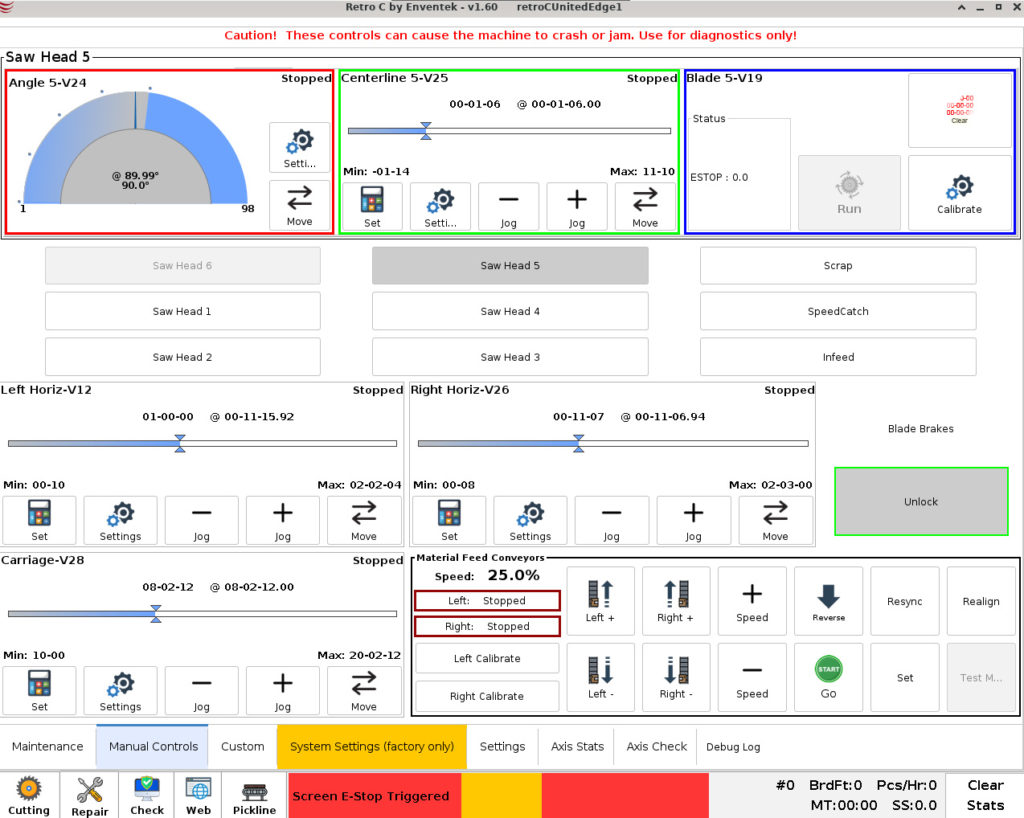

To get to the window below for any angle or centerline all you have to do is select the head you want to work on and press “settings”.

In the image below “Saw Head 5” was selected. Next, press the “settings” button on either the angle or the centerline. Once you are on this screen use the Forward or Back icons to move the head using its maximum power.

If you are unable to move the head from the calibration window (not uncommon) proceed to step 2.

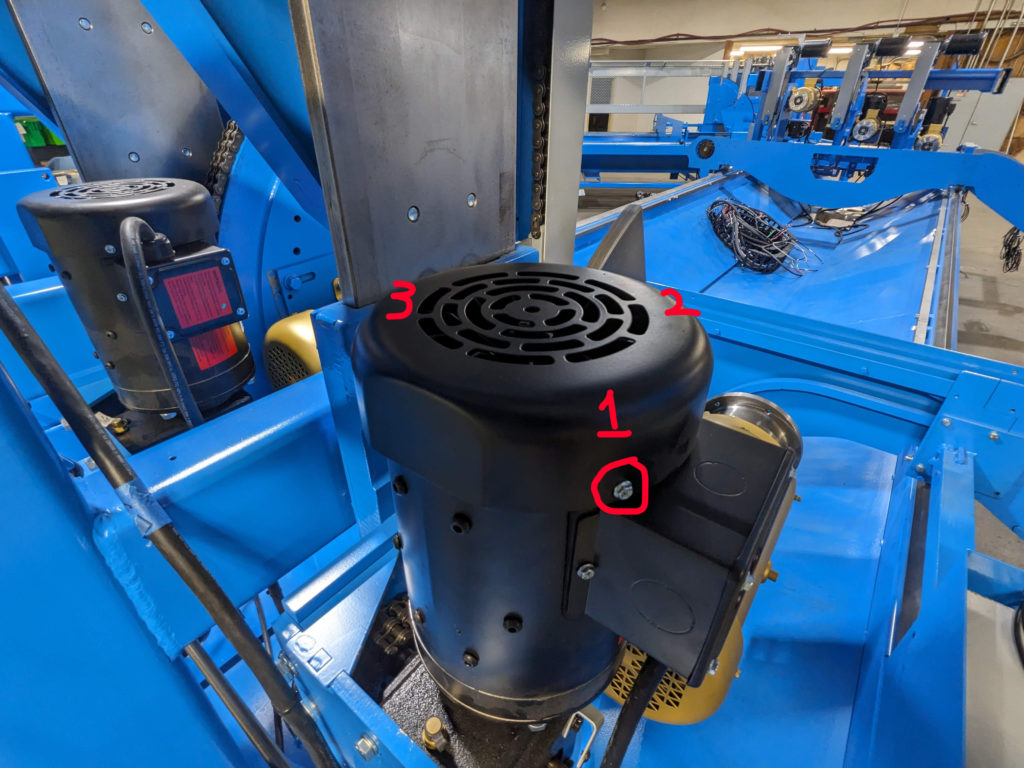

STEP 2: Remove the Fan Cover and Spin the Shaft

There are (3) 1/4′ screws that hold the fan cover in place, remove all 3 and take the cover off (screws 2 & 3 are not visible).

If the motor was NOT jammed very hard against the end stop you may be able to spin the (plastic) fan blades by hand. Watch this video.

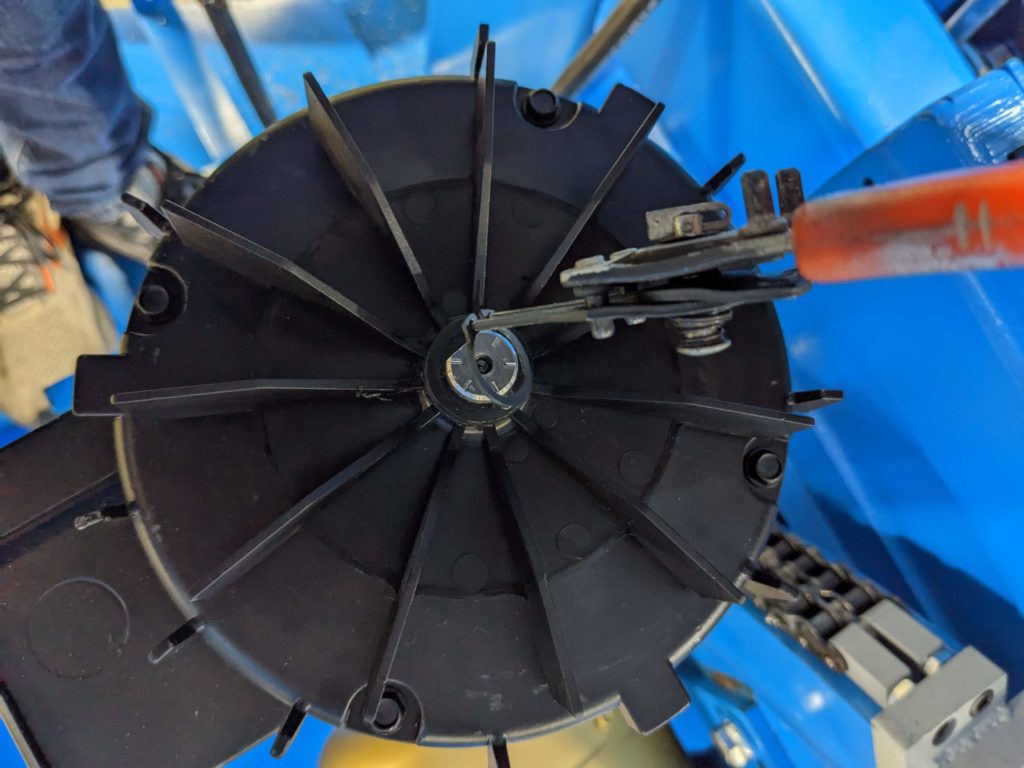

Most often spinning the blades by hand isn’t going to give you enough torque since the fan blades are made of plastic, so you will need to spin the shaft. To be able to get enough “bite” on the shaft you will need to remove the snap ring holding the fan in place

With the snap ring off you should be able to get enough bite with a pair of Vice Grips or Channellocks to spin the shaft clockwise or counterclockwise.

Fan Rotation – Stuck Centerline

If the Centerline is stuck at the top position you will want to spin the fan/shaft clockwise.

If the Centerline is stuck at the bottom you will want to spin the fan/shaft counterclockwise.

Fan Rotation – Stuck Angle

For the Angles, spinning the fan/shaft clockwise will free you if you are stuck on the bottom end stop.

Turn the fan/shaft counterclockwise if the angle is stuck on the top hard stop

Once you have freed the angle or centerline you are working be sure to replace the snap ring and the fan cover/screws.

Step 3 – Re-Calibrating the Max/Min positions in the software.

After freeing an angle or centerline the last step is always going to be to re-calibrate the max and min position of that movement so this doesn’t happen again. To do this watch this Video (coming soon)