Search for answers or browse our knowledge base.

Emergency Stop

The emergency stop starts at S11 on the Estop relay and travels through a relay that must have at vc1 output 7 turned on. This allows the software to e-stop the system as needed when there are potential issues.

It then travels to the pneumatic sensor (Air Pressure CR27) which must have air pressure of at least 75 psi in order to operate the saw.

From the pneumatic sensor it’s then goes to the cable pull (Pull Cord PB10) that travels around the saw.

From the cable pull it goes to the touch screen emergency stop (PB11).

From the touch screen emergency stop it travels to the key lockout tagout (PB12).

Finally from the key lockout tagout it travels back to the emergency stop relay into S31 and S32. (Orange)

The arrows show the route of travel. The emergency stop system consists of a pair of +24 volt wires the travel through sensors or switches. At any point if the either of the +24 volt wires are broken then the emergency stop is engaged.

The green labels above are the wire labels.

The squares are the red terminals on the stationary side of the saw.

The teal are terminal labels which are either labeled on the terminal blocks or the component itself.

There are sensor wires that go to V5 and V7 inputs that detect a break in the system. However note that at this time 71,73 and 75 are not sensed. If there is a switch with an issue on one terminal it may not show the exact location due to the sensor points.

E-Stop Terminals

The Estop terminals are located in the top right of the stationary electrical panel. They look like the image below. When the emergency stop is disabled terminals 70 – 76 should all have +24v. They also should all have continuity starting at 70 and going to 76.

Pneumatic Sensor

The Pneumatic sensor detects if there is enough air pressure available for the machine to operate if the air pressure is below 75 psi It will fire an emergency stop until the pressure is restored.

Below is the sensor which wires into CR27. There is a light on CR27 which should be on if there is air pressure.

Cable Pull Emergency Stop

The Cable Pull is after the Air Pressure sensor. In order for power to pass through the Cable pull switch the sensor indicator must be in the center on the line. If the cable is too lose or to tight it will act as if the machine is in an emergency stop state. This safety feature works if a user pulls the cable or if it gets broken.

Touchscreen Emergency stop switch

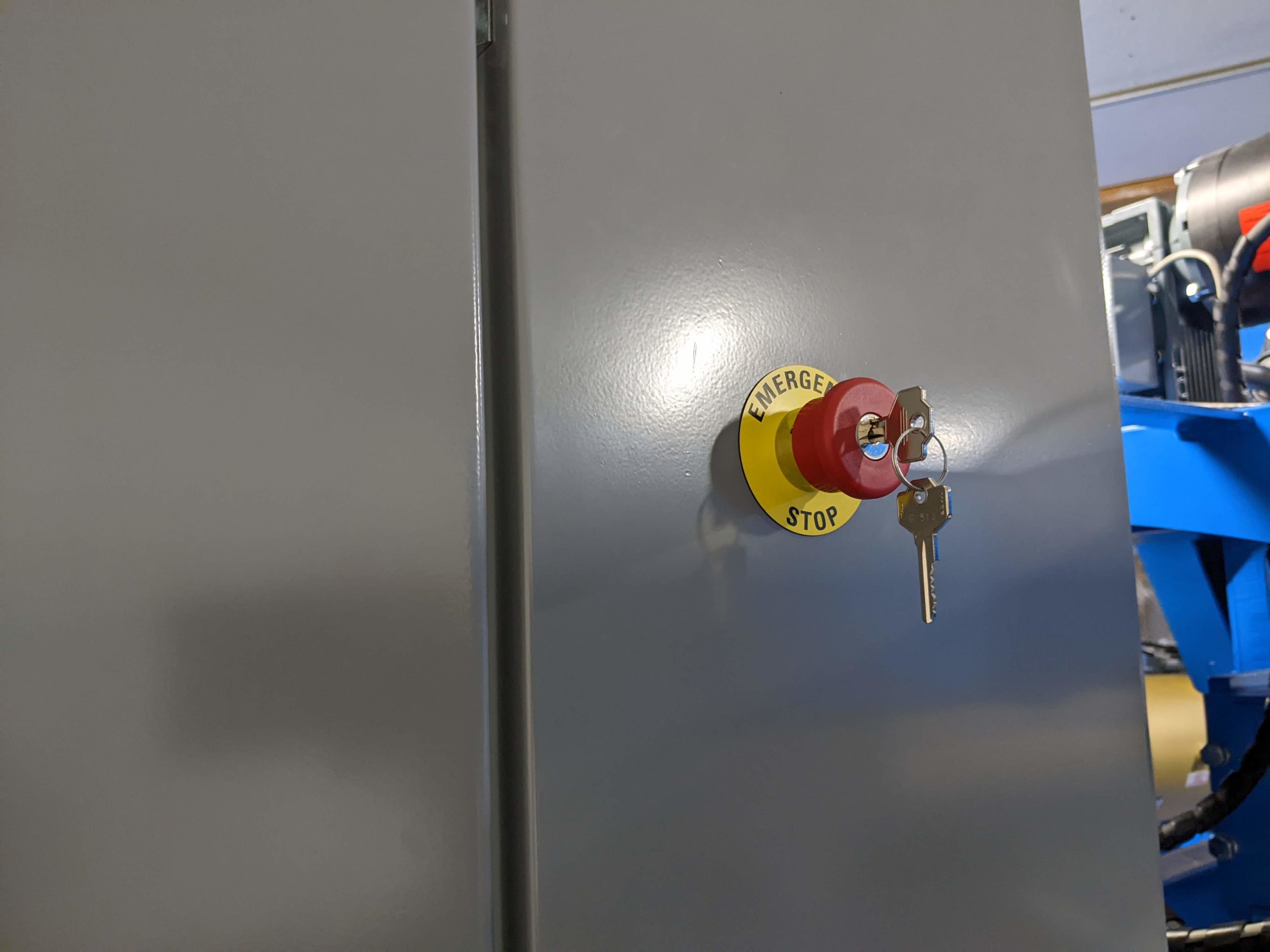

Safety Key Emergency stop switch

This switch helps for lockout/tag out as when the switch is pushed and the key is taken it can not be unlocked until the key is returned. Note: Each company should have its own lockout/tagout procedure however this will help with that process.