How Can We Help?

Search for answers or browse our knowledge base.

-

Retro C

-

-

- Articles coming soon

-

- Configuring the Touchscreen Computer's "Power-On"

- How to replace micro USB on the display computers

- How to Replace the Retro C's Computer

- How to replace the USB hard drive on the touch screen computer

- How To: Transfer Files to the Retro C

- New computer set bios power on

- Old computer set bios to power on

- TouchScreen Flip / Mirror Issue

-

-

-

- Angle (Arch) Movements - Overview

- Angle Chains - Proper Chain Tension

- Angle movements over run when going to position.

- Diagnosing Unknown Noises Coming from Blade Motor

- Pivot Point Check

- Power or Wiring Troubleshooting for Angle Motors or VFDs

- Replacing an Angle Encoder

- Stuck Angle or Centerline - How to Recover & Recalibrate

-

- Centerline (Vertical) Movements - Overview

- Checking the Centerline Maximum & Minimum (Max & Min) Height Setting

- How to set the "Minimum" position for Blade #5

- How to Tighten the Centerline Slides

- How To: Calibrate Centerline 1-5

- How To: Calibrate Centerline 1-5 (Advanced)

- How To: Tension The Centerline Chains

- Replacing a Centerline Encoder

- Replacing a Centerline Gearbox

- Stuck Angle or Centerline - How to Recover & Recalibrate

-

-

-

- Common Retro C issues and solutions

- Countdown Timer / E-Stop Troubleshooting

- Scrap Belt or Scrap Incline VFD Disconnected: Troubleshooting

- Stuck Angle or Centerline - How to Recover & Recalibrate

- TouchScreen Flip / Mirror Issue

- Troubleshooting: Encoder Unplugged Error

- Troubleshooting: The Stationary or Carriage Side Horizontals Won't Move Anymore

-

-

Linear Pickline

-

Plant One Projection

-

SmartConveyor

-

Sticker Printer

< All Topics

Print

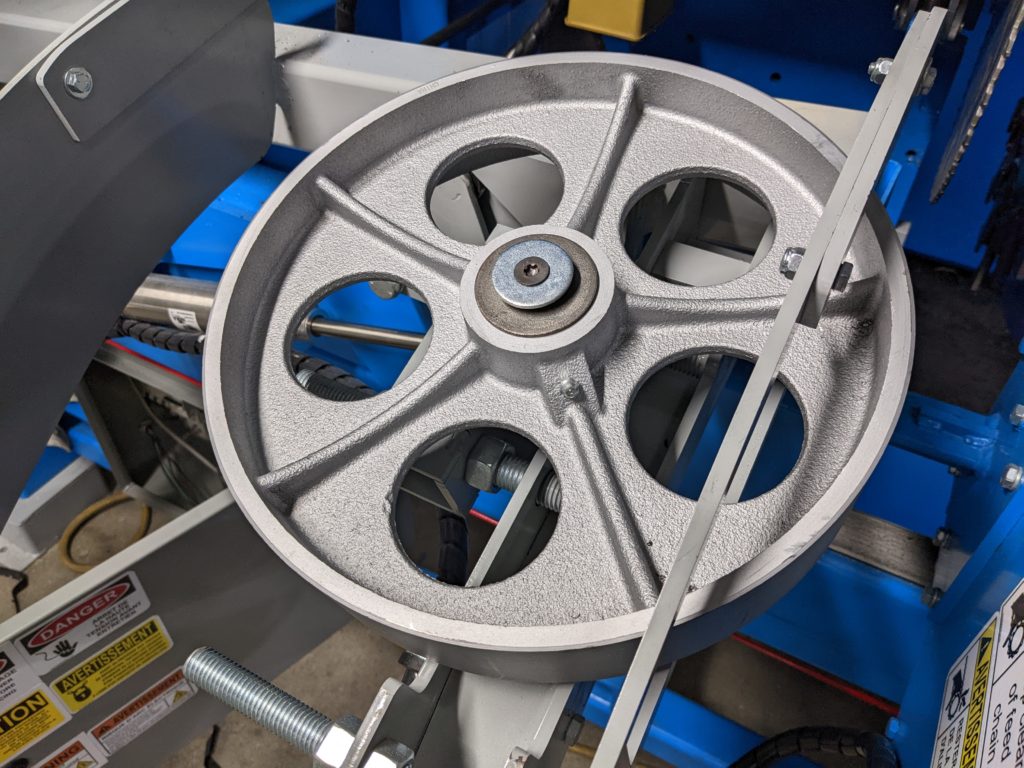

Adjusting the Position of the Guide Wheel

UpdatedFebruary 21, 2024

The lumber guide wheel is the final point of adjustment for the lumber before it is cut. The guide wheels job is to position the lumber so that it is inline with saw blade 1 and 2. If you find that the lumber isn’t being cut at all (the wheel is pushing the lumber too far to the right or isn’t pushing it in far enough and is consistently cutting length off of the lumber when it is a doing a standard 90 degree cut adjusting the wheel position can help.

To adjust follow these steps:

Step 1: Loosen two of the jam nuts on the threaded rod under the wheel (there are four total). Move the wheel in or out depending on what issue you are trying to correct and then retighten the jam nuts.

Table of Contents