Search for answers or browse our knowledge base.

-

Retro C

-

-

- Articles coming soon

-

- Configuring the Touchscreen Computer's "Power-On"

- How to replace micro USB on the display computers

- How to Replace the Retro C's Computer

- How to replace the USB hard drive on the touch screen computer

- How To: Transfer Files to the Retro C

- New computer set bios power on

- Old computer set bios to power on

- TouchScreen Flip / Mirror Issue

-

-

-

- Angle (Arch) Movements - Overview

- Angle Chains - Proper Chain Tension

- Angle movements over run when going to position.

- Diagnosing Unknown Noises Coming from Blade Motor

- Pivot Point Check

- Power or Wiring Troubleshooting for Angle Motors or VFDs

- Replacing an Angle Encoder

- Stuck Angle or Centerline - How to Recover & Recalibrate

-

- Centerline (Vertical) Movements - Overview

- Checking the Centerline Maximum & Minimum (Max & Min) Height Setting

- How to set the "Minimum" position for Blade #5

- How to Tighten the Centerline Slides

- How To: Calibrate Centerline 1-5

- How To: Calibrate Centerline 1-5 (Advanced)

- How To: Tension The Centerline Chains

- Replacing a Centerline Encoder

- Replacing a Centerline Gearbox

- Stuck Angle or Centerline - How to Recover & Recalibrate

-

-

-

- Common Retro C issues and solutions

- Countdown Timer / E-Stop Troubleshooting

- Scrap Belt or Scrap Incline VFD Disconnected: Troubleshooting

- Stuck Angle or Centerline - How to Recover & Recalibrate

- TouchScreen Flip / Mirror Issue

- Troubleshooting: Encoder Unplugged Error

- Troubleshooting: The Stationary or Carriage Side Horizontals Won't Move Anymore

-

-

Linear Pickline

-

Plant One Projection

-

SmartConveyor

-

Sticker Printer

Linear Pickline – How to ReTeach a Sensor

If a sensor malfunctions and is constantly sensing in the on or off position, you may need to simply “re-teach” the sensor. This is very easy to do and should take 5 minutes or less.

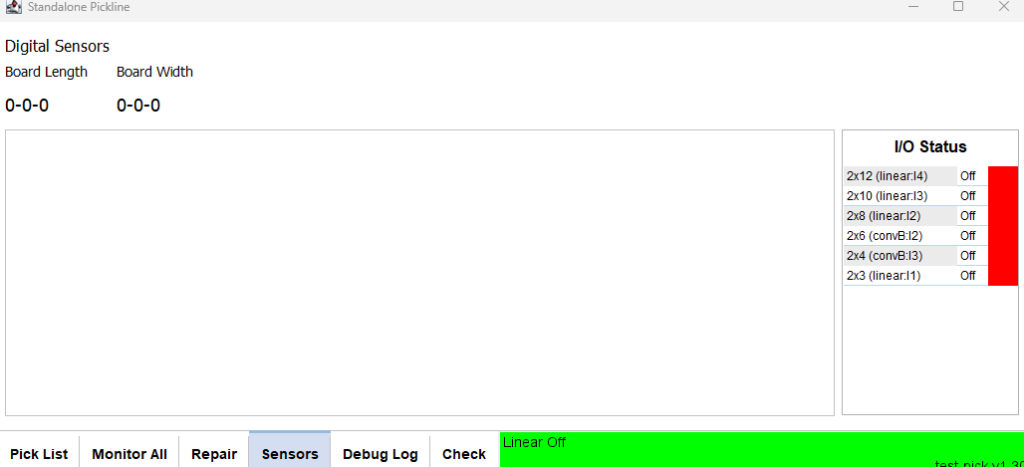

The sensor diagnostics is under the Sensors tab. This is located in the pickline software if this is a RetroC it will be under the Pickline tab and then under sensors.

The lights on the right of the screen below are all off currently. They will turn green if they are active. This can help with diagnostics.

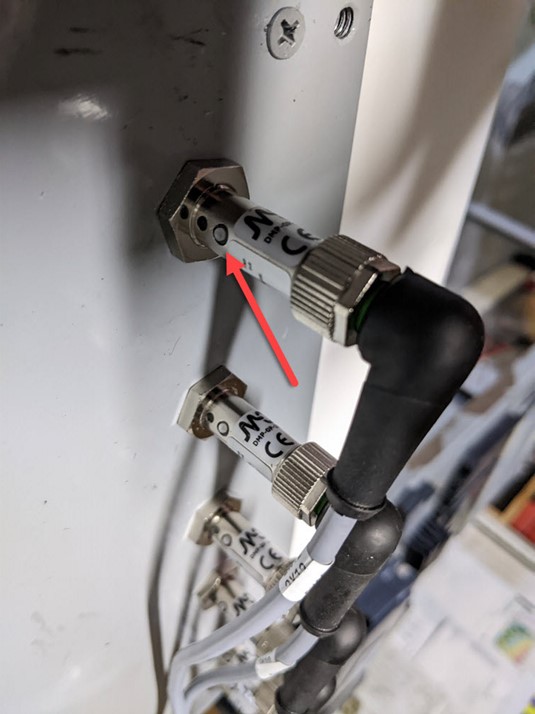

Step 1: Check that there is no debris between the sensor eyes and the reflector before teaching the machine. The sensor are located behind the cover in the lower image.

Step 2: Take the cover off of the sensor unit. The are four 1/4″ bolts holding it in place (only 2 are shown). Use a 7/16 socket or wrench to remove the cover.

Step 3: Press and hold the teach button of the sensor you want to re-teach for 3 seconds without anything covering the sensor. It must see the reflector in order to teach the sensor properly.

Step 4: Load a board into the machine and confirm that each sensor works properly.

Step 5: Replace the cover with the 4 bolts using the 7/16 socket set.