Search for answers or browse our knowledge base.

-

Retro C

-

-

- Articles coming soon

-

- Configuring the Touchscreen Computer's "Power-On"

- How to replace micro USB on the display computers

- How to Replace the Retro C's Computer

- How to replace the USB hard drive on the touch screen computer

- How To: Transfer Files to the Retro C

- New computer set bios power on

- Old computer set bios to power on

- TouchScreen Flip / Mirror Issue

-

-

-

- Angle (Arch) Movements - Overview

- Angle Chains - Proper Chain Tension

- Angle movements over run when going to position.

- Diagnosing Unknown Noises Coming from Blade Motor

- Pivot Point Check

- Power or Wiring Troubleshooting for Angle Motors or VFDs

- Replacing an Angle Encoder

- Stuck Angle or Centerline - How to Recover & Recalibrate

-

- Centerline (Vertical) Movements - Overview

- Checking the Centerline Maximum & Minimum (Max & Min) Height Setting

- How to set the "Minimum" position for Blade #5

- How to Tighten the Centerline Slides

- How To: Calibrate Centerline 1-5

- How To: Calibrate Centerline 1-5 (Advanced)

- How To: Tension The Centerline Chains

- Replacing a Centerline Encoder

- Replacing a Centerline Gearbox

- Stuck Angle or Centerline - How to Recover & Recalibrate

-

-

-

- Common Retro C issues and solutions

- Countdown Timer / E-Stop Troubleshooting

- Scrap Belt or Scrap Incline VFD Disconnected: Troubleshooting

- Stuck Angle or Centerline - How to Recover & Recalibrate

- TouchScreen Flip / Mirror Issue

- Troubleshooting: Encoder Unplugged Error

- Troubleshooting: The Stationary or Carriage Side Horizontals Won't Move Anymore

-

-

Linear Pickline

-

Plant One Projection

-

SmartConveyor

-

Sticker Printer

Troubleshooting Network Issues

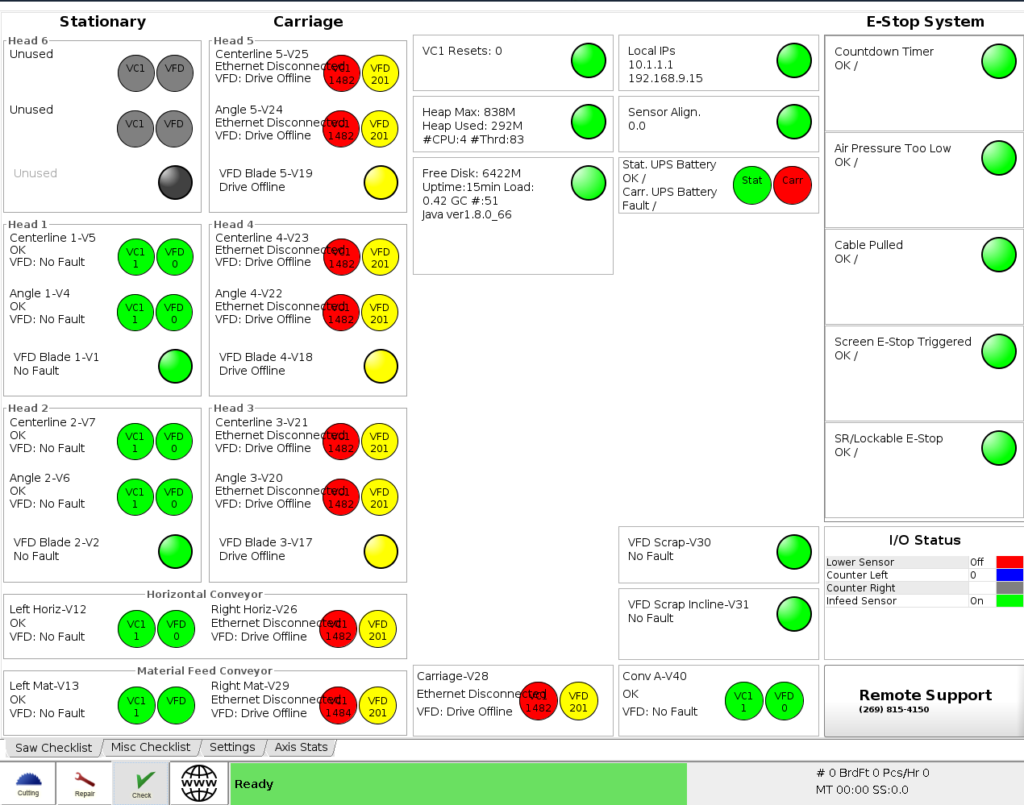

Communication between drives, motors, and computers is all handled over cat5 ethernet cables. This page will go over some of the most common issues and how to troubleshoot them when they arise. First a little refresher:

The Stationary Side

The (Blue) wires connect each of the head’s VC1s on the stationary side to the network switch.

The (Gray) CBL Net cable connects to the “Smart Conveyor” (infeed conveyor).

The (Gray) TV_Net cable connects to the “rear tv” that is mounted on the rearguard.

The (Gray) Carr_Net cable connects the stationary side of the saw with the carriage side of the saw. This cable runs from switch to switch.

The (Gray) Comp_Net cable connects with the network switch located inside the touchscreen enclosure.

Carriage Side

The (Blue) wires connect each of the head’s VC1s on the carriage side to the network switch.

The (Gray) Carr_Net cable connects the carriage side of the saw with the stationary side of the saw. This cable runs from switch to switch.

Troubleshooting

- One common issue is that the “Check” screen shows all of the VC1s on the Carriage side of the saw as disconnected.

When you see this it typically means there is an issue with the “Carr_Net” cable that connects the stationary side’s network switch with the carriage’s switch.

- One or both ends of the cable are unplugged.

- The network switch on the carriage side is unplugged/lost power or has died. Are there any green flashing lights? If not, is the switch powered on or is it dead and needs to be replaced?

- The ethernet cable labeled “Carr_Net” has been pinched/cut somewhere.