Search for answers or browse our knowledge base.

-

Retro C

-

-

- Articles coming soon

-

- Configuring the Touchscreen Computer's "Power-On"

- How to replace micro USB on the display computers

- How to Replace the Retro C's Computer

- How to replace the USB hard drive on the touch screen computer

- How To: Transfer Files to the Retro C

- New computer set bios power on

- Old computer set bios to power on

- TouchScreen Flip / Mirror Issue

-

-

-

- Angle (Arch) Movements - Overview

- Angle Chains - Proper Chain Tension

- Angle movements over run when going to position.

- Diagnosing Unknown Noises Coming from Blade Motor

- Pivot Point Check

- Power or Wiring Troubleshooting for Angle Motors or VFDs

- Replacing an Angle Encoder

- Stuck Angle or Centerline - How to Recover & Recalibrate

-

- Centerline (Vertical) Movements - Overview

- Checking the Centerline Maximum & Minimum (Max & Min) Height Setting

- How to set the "Minimum" position for Blade #5

- How to Tighten the Centerline Slides

- How To: Calibrate Centerline 1-5

- How To: Calibrate Centerline 1-5 (Advanced)

- How To: Tension The Centerline Chains

- Replacing a Centerline Encoder

- Replacing a Centerline Gearbox

- Stuck Angle or Centerline - How to Recover & Recalibrate

-

-

-

- Common Retro C issues and solutions

- Countdown Timer / E-Stop Troubleshooting

- Scrap Belt or Scrap Incline VFD Disconnected: Troubleshooting

- Stuck Angle or Centerline - How to Recover & Recalibrate

- TouchScreen Flip / Mirror Issue

- Troubleshooting: Encoder Unplugged Error

- Troubleshooting: The Stationary or Carriage Side Horizontals Won't Move Anymore

-

-

Linear Pickline

-

Plant One Projection

-

SmartConveyor

-

Sticker Printer

How to set the “Minimum” position for Blade #5

If you get the error “Stall: Centerline 5-v25” during a setup, it can be because blade 5 is hitting the end stop. One possible reason this could be occurring is that the saw is out of calibration and the minimum position (the lowest possible position the centerline can go before hitting the end stop) needs to be recalibrated.

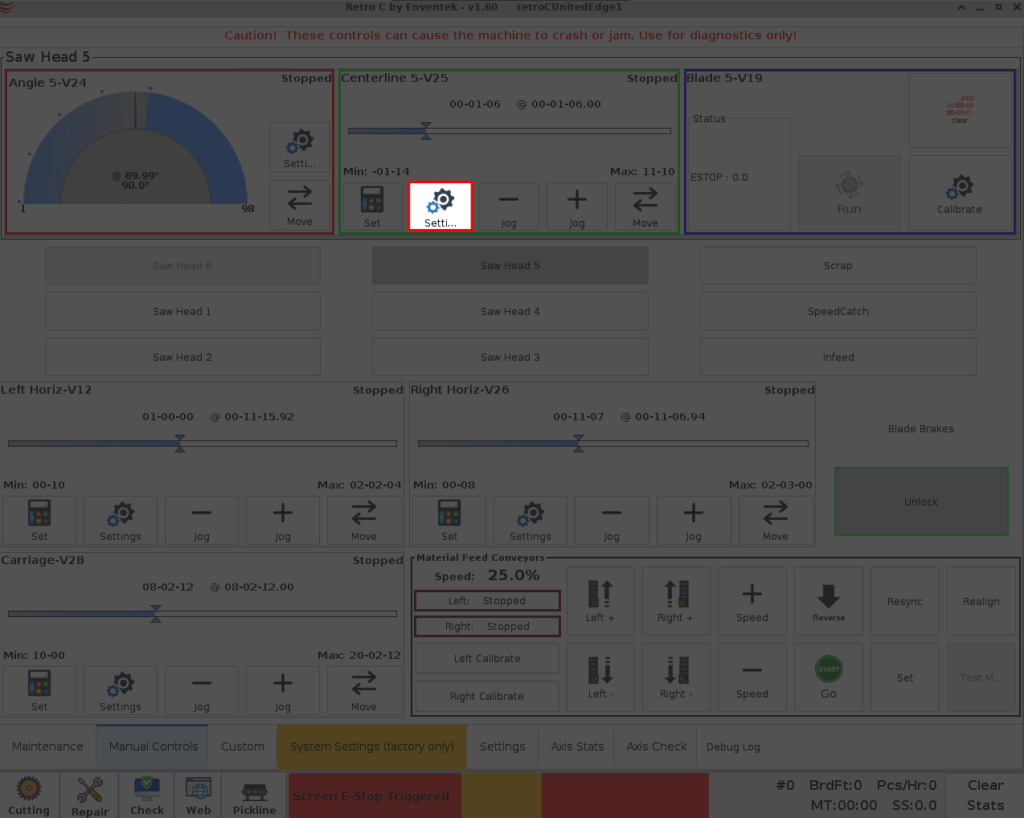

Step 1: To recalibrate the centerlines’ minimum position select “Saw Head 5” in the “Manual Controls” window and press the “Settings” button.

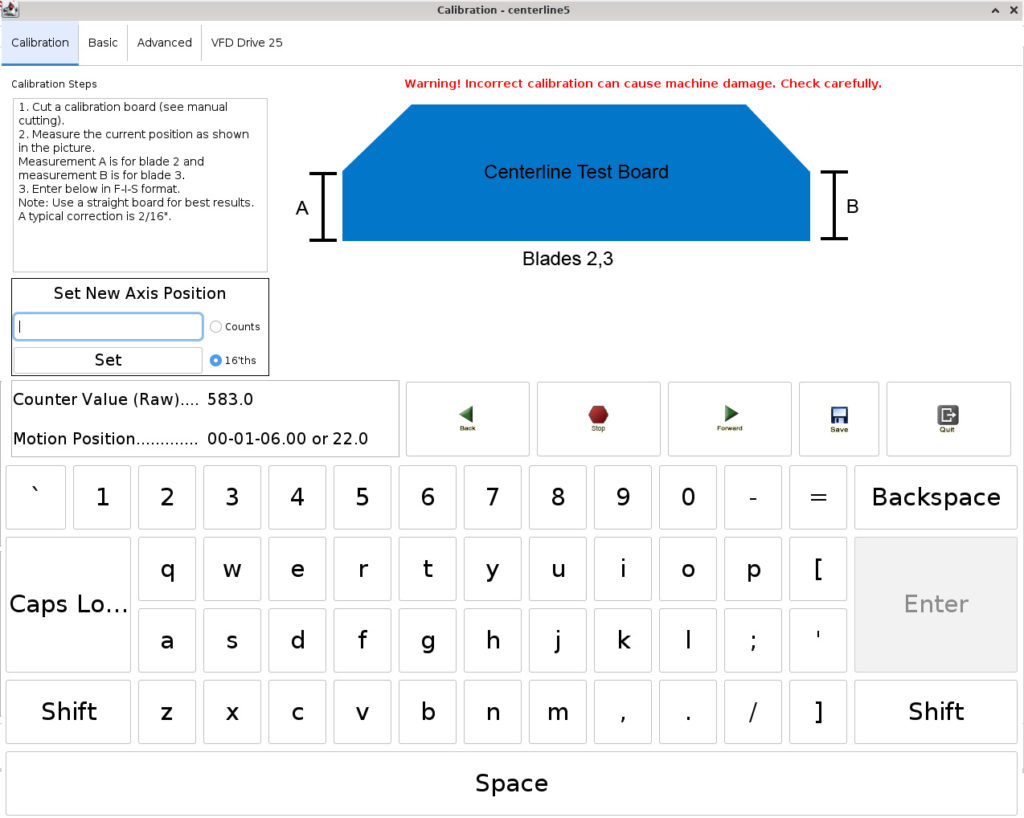

Step 2: On the Calibration tab for the “Centerline” for Blade 5 press the “Back” (left triangle symbol) button, which will move the head down, until the motor stalls out because it has hit the end stop.

Step 3: Press the “Forward” button and then the “Stop” button to move the centerline about 1/16th of an inch away from the end stop.

NOTE: The reason we move the saw 1/16th away from the end stop is so there is a small buffer between what the software thinks is the minimum position and what the actual minimum is, basically we don’t want to have the centerline hit the end stop if we can help it.

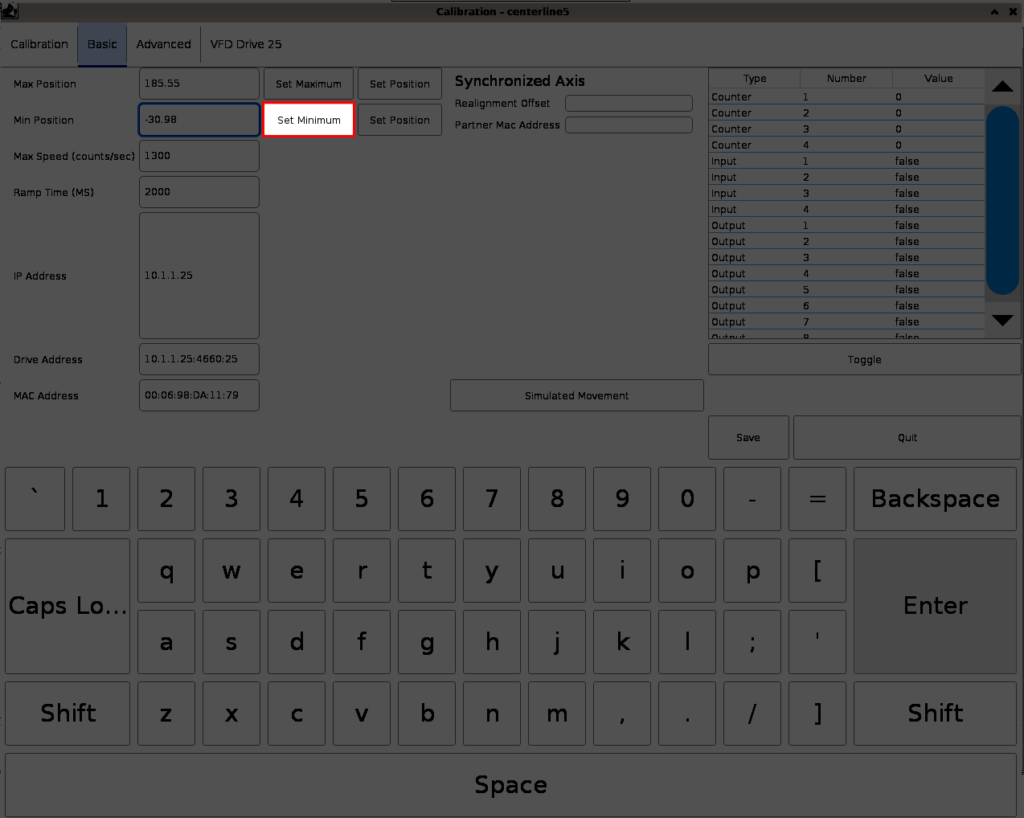

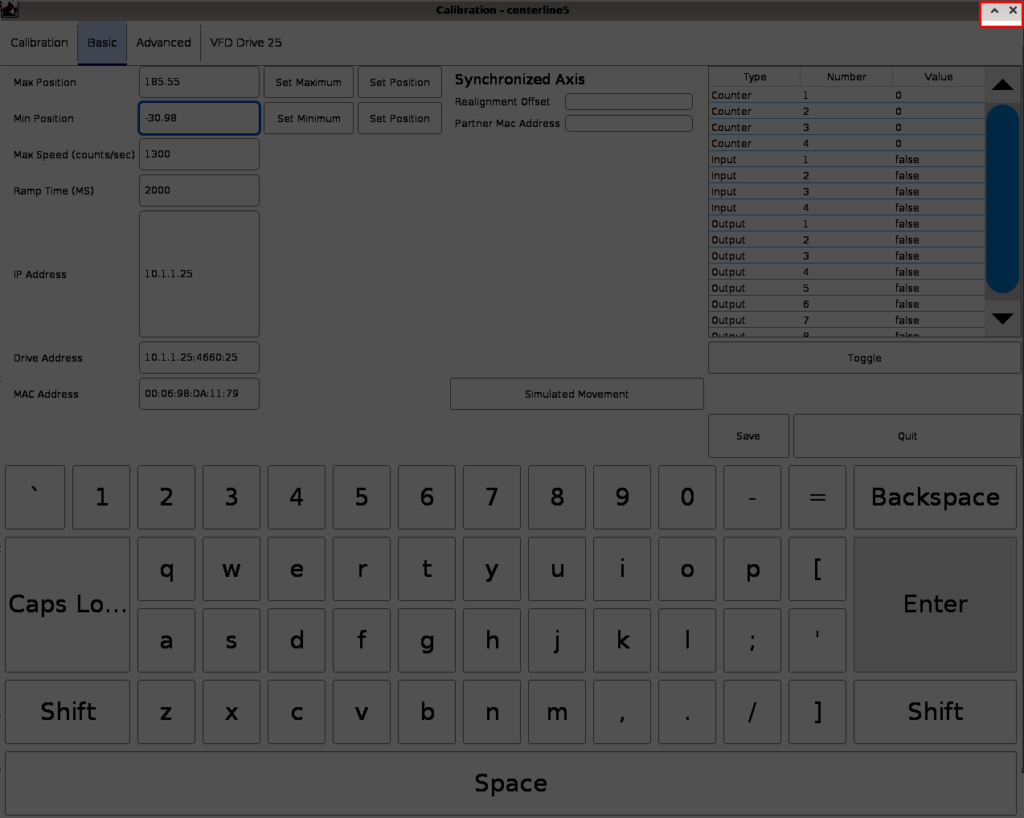

Step 4: Select the “Basic” tab at the top of the screen and press the button labeled “Set Minimum”.

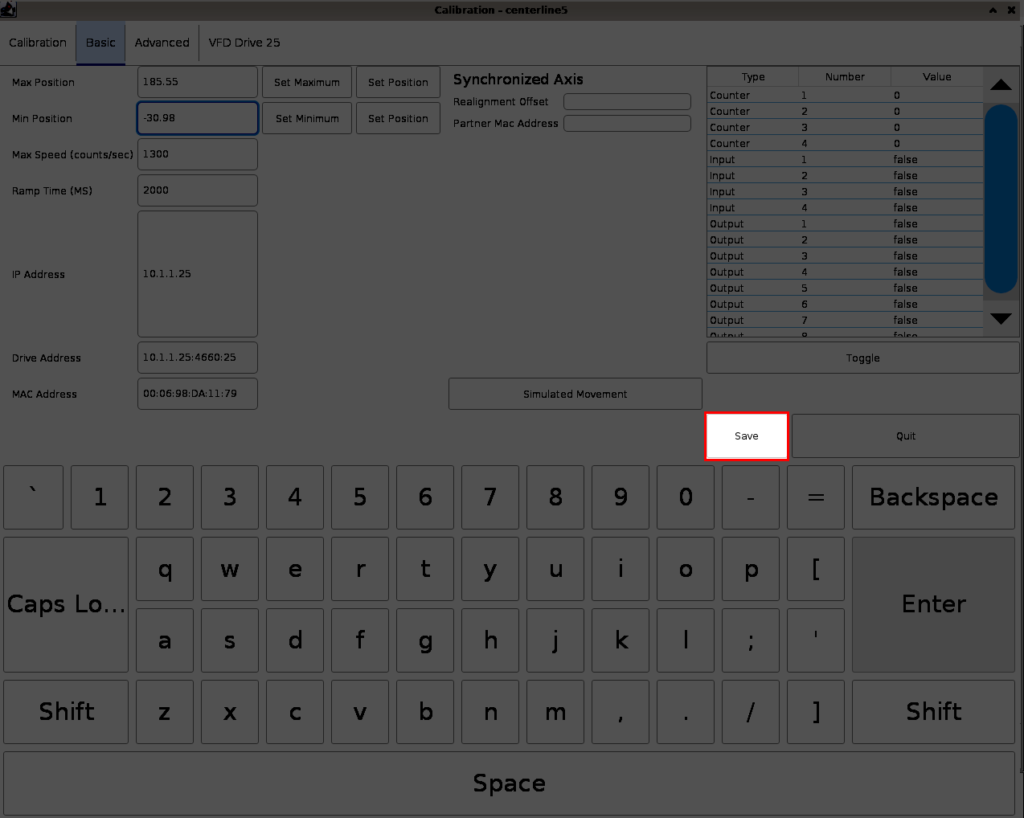

Step 5: Press the “Save” button

Step 6: Restart the software by pressing the “X” at the top right of the screen.

That’s it, you have now updated the saw’s minimum centerline position for head #5.