Search for answers or browse our knowledge base.

-

Retro C

-

-

- Articles coming soon

-

- How to Replace the Retro C's Computer

- Configuring the Touchscreen Computer's "Power-On"

- How to replace micro USB on the display computers

- How To: Transfer Files to the Retro C

- How to replace the USB hard drive on the touch screen computer

- New computer set bios power on

- Old computer set bios to power on

- TouchScreen Flip / Mirror Issue

-

-

-

- Stuck Angle or Centerline - How to Recover & Recalibrate

- Replacing an Angle Encoder

- Angle movements over run when going to position.

- Angle (Arch) Movements - Overview

- Angle Chains - Proper Chain Tension

- Diagnosing Unknown Noises Coming from Blade Motor

- Pivot Point Check

- Power or Wiring Troubleshooting for Angle Motors or VFDs

-

- Stuck Angle or Centerline - How to Recover & Recalibrate

- How To: Calibrate Centerline 1-5

- How To: Calibrate Centerline 1-5 (Advanced)

- Centerline (Vertical) Movements - Overview

- Replacing a Centerline Encoder

- Replacing a Centerline Gearbox

- Checking the Centerline Maximum & Minimum (Max & Min) Height Setting

- How to Tighten the Centerline Slides

- How To: Tension The Centerline Chains

-

-

-

- Common Retro C issues and solutions

- Countdown Timer / E-Stop Troubleshooting

- Scrap Belt or Scrap Incline VFD Disconnected: Troubleshooting

- Stuck Angle or Centerline - How to Recover & Recalibrate

- TouchScreen Flip / Mirror Issue

- Troubleshooting: Encoder Unplugged Error

- Troubleshooting: The Stationary or Carriage Side Horizontals Won't Move Anymore

-

-

Linear Pickline

-

Plant One Projection

-

SmartConveyor

-

Sticker Printer

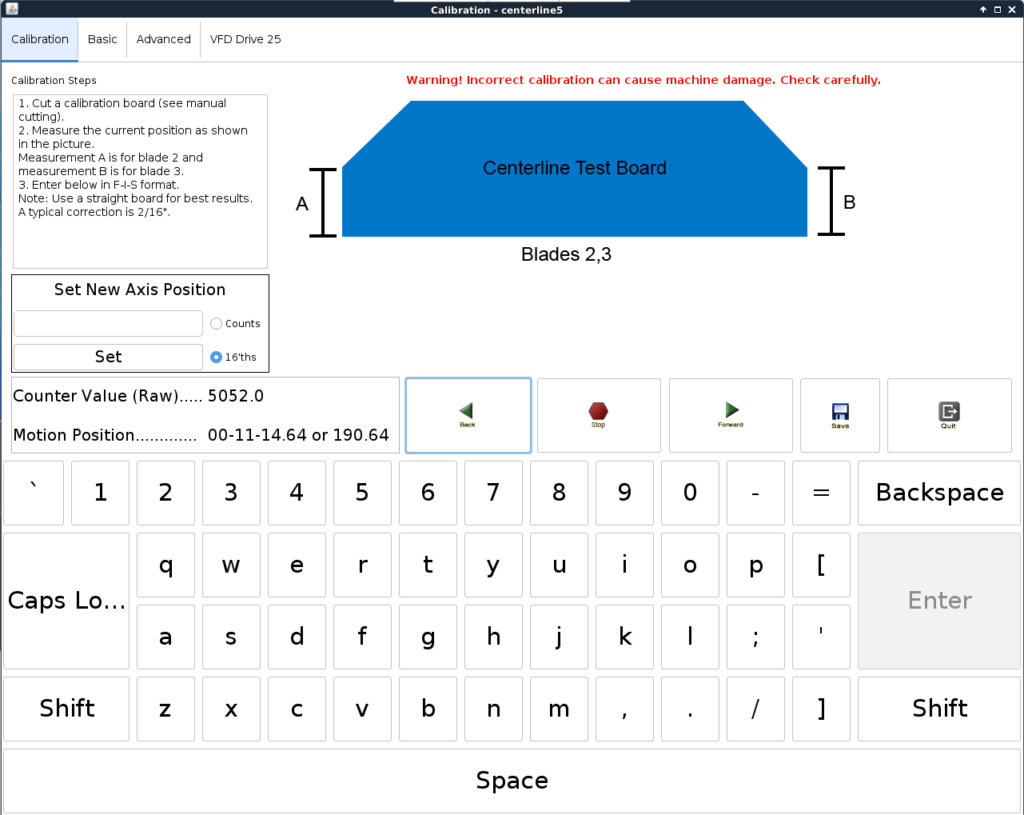

How To: Calibrate Centerline 1-5 (Advanced)

There are a number of reasons you might need to recalibrate your centerline. The most common reasons are:

- Older Retro C saws use screw drive centerlines that tended to fade down more often than our newer chain drive systems.

- Loss of power while the saw head was moving.

- Crashing lumber against the saw head.

- Improper calibration (we’re all human, it happens).

This article will help you calibrate your saw if it is so far out of calibration that you can’t run through the normal steps. Usually, this happens if there is a power loss during a move or if a human has improperly tried to calibrate a saw/hit the wrong button, etc.

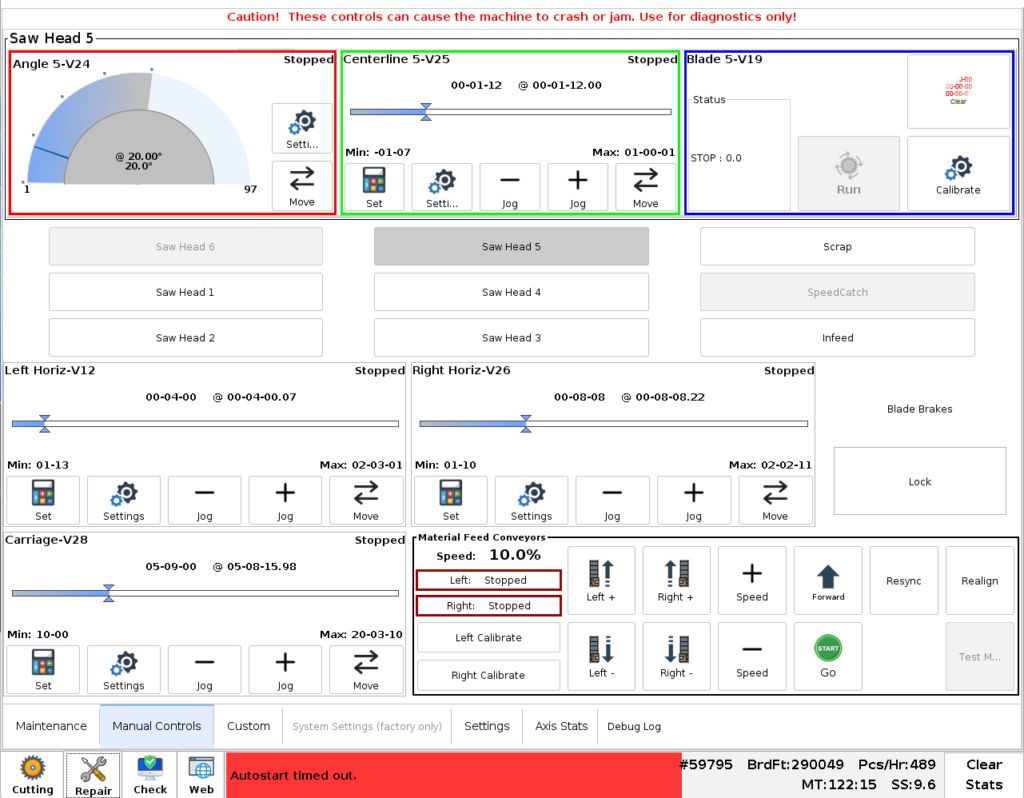

Step 1: Go into the “Repair” & then “Manual Controls” tab and select the saw head and the centerline you want to fix.

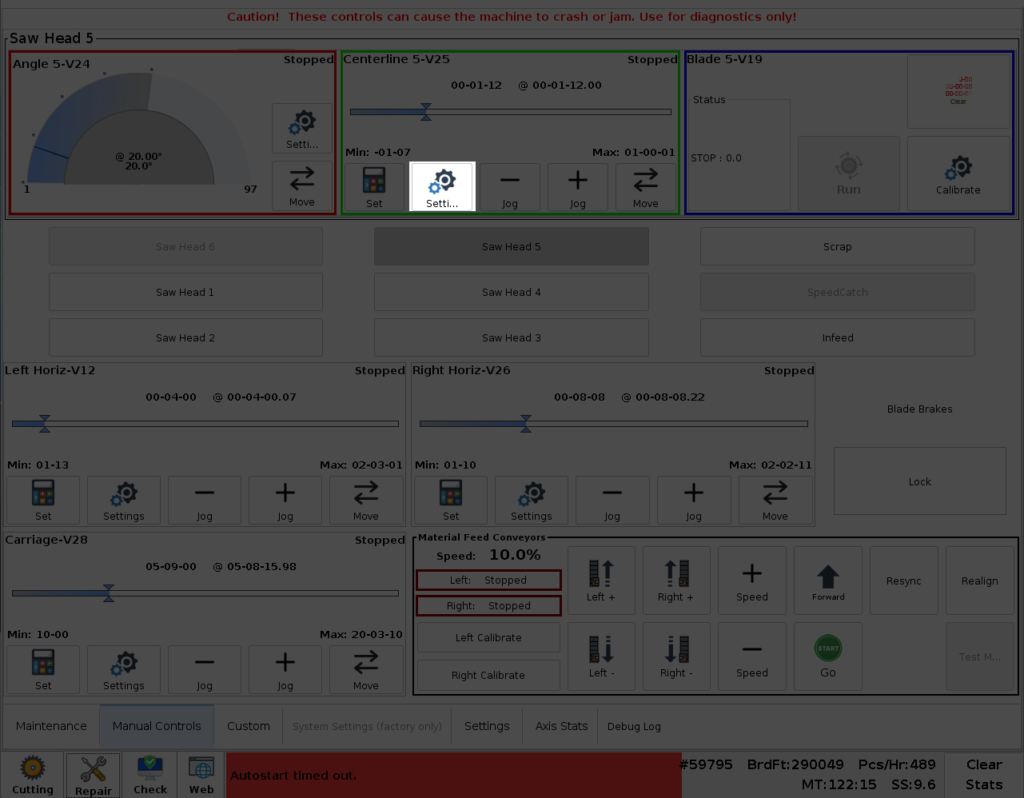

For this example, I am going to use Centerline #5. Press the “Settings” button.

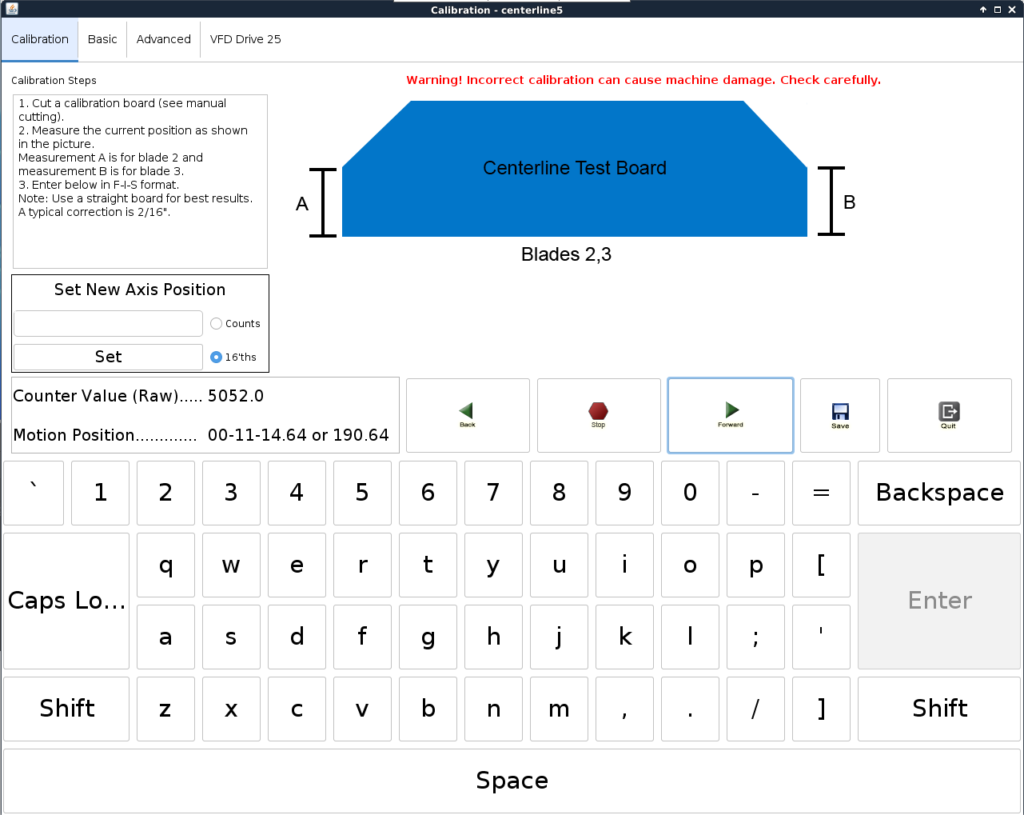

Move the centerline all the way to the top and let it hit the end stop by pressing the “Forward” button. Wait until it stalls and can’t move any higher. Note the value listed in the “motion position” (190.64 in this example).

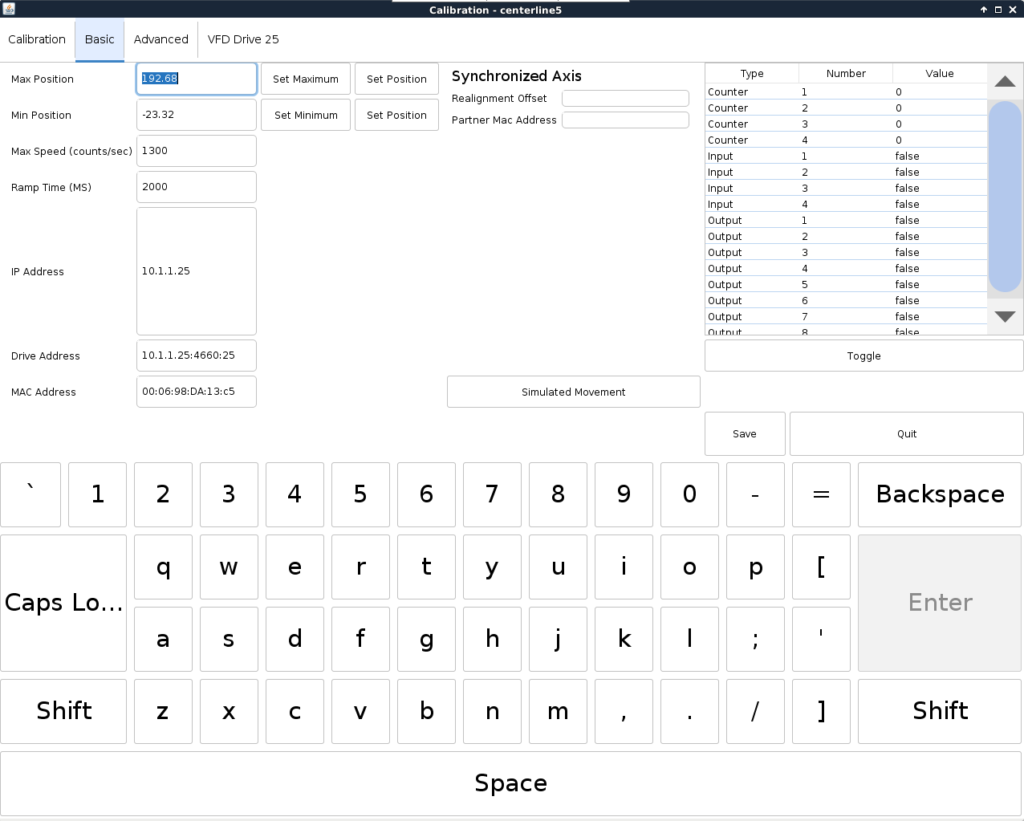

Next, go to the “Basic” tab and see if the number in the “Max Position” field matches. If not, press “Set Position” (don’t press both buttons labeled Set Position, just the one that corresponds to the Max Position).

Go back to the “Calibration” tab and use the “back” button to move the centerline down (off) of its hard stop. You can move it any distance (it doesn’t have to be far), the reason for this is that the motor will likely stall the next time you move to a setup if you don’t move it in this window. NOTE: using the controls on this screen allows the motor to use 100% of its power vs 90% in the normal cutting window.

Now that you have verified that the centerline is within its “max bounds” go through the standard calibration process on the “Repair” & “Maintenance” tab.