Search for answers or browse our knowledge base.

-

Retro C

-

-

- Articles coming soon

-

- How to Replace the Retro C's Computer

- Configuring the Touchscreen Computer's "Power-On"

- How to replace micro USB on the display computers

- How To: Transfer Files to the Retro C

- How to replace the USB hard drive on the touch screen computer

- New computer set bios power on

- Old computer set bios to power on

- TouchScreen Flip / Mirror Issue

-

-

-

- Stuck Angle or Centerline - How to Recover & Recalibrate

- Replacing an Angle Encoder

- Angle movements over run when going to position.

- Angle (Arch) Movements - Overview

- Angle Chains - Proper Chain Tension

- Diagnosing Unknown Noises Coming from Blade Motor

- Pivot Point Check

- Power or Wiring Troubleshooting for Angle Motors or VFDs

-

- Stuck Angle or Centerline - How to Recover & Recalibrate

- How To: Calibrate Centerline 1-5

- How To: Calibrate Centerline 1-5 (Advanced)

- Centerline (Vertical) Movements - Overview

- Replacing a Centerline Encoder

- Replacing a Centerline Gearbox

- Checking the Centerline Maximum & Minimum (Max & Min) Height Setting

- How to Tighten the Centerline Slides

- How To: Tension The Centerline Chains

-

-

-

- Common Retro C issues and solutions

- Countdown Timer / E-Stop Troubleshooting

- Scrap Belt or Scrap Incline VFD Disconnected: Troubleshooting

- Stuck Angle or Centerline - How to Recover & Recalibrate

- TouchScreen Flip / Mirror Issue

- Troubleshooting: Encoder Unplugged Error

- Troubleshooting: The Stationary or Carriage Side Horizontals Won't Move Anymore

-

-

Linear Pickline

-

Plant One Projection

-

SmartConveyor

-

Sticker Printer

Adjusting or Tightening the Scrap Conveyor Belt

If the scrap belt is slipping on the roller or not staying centered manual adjustment is required.

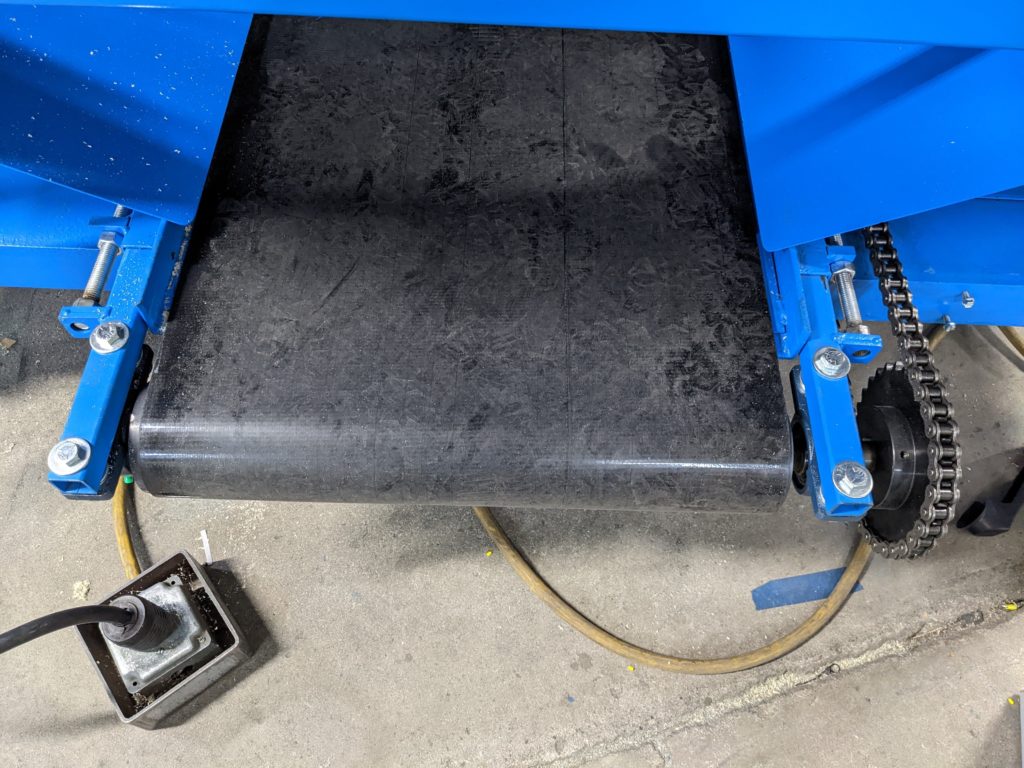

- Step 1: Remove the gray chain guard so you have more room to work. There are two bolts on the right side of the cover that hold it in place. Once the bolts are removed it slides right off.

- Step 2: Verify that the chain is tight on the gear itself and doesn’t slip when the conveyor is on.

- Step 3: Loosen the locknut on each of the tensioning bolts.

It is important to evenly extend both sides of the tensioning system so that the belt stays centered when running. If it does become uncentered you will need to tighten or loosen one side or the other to compensate.

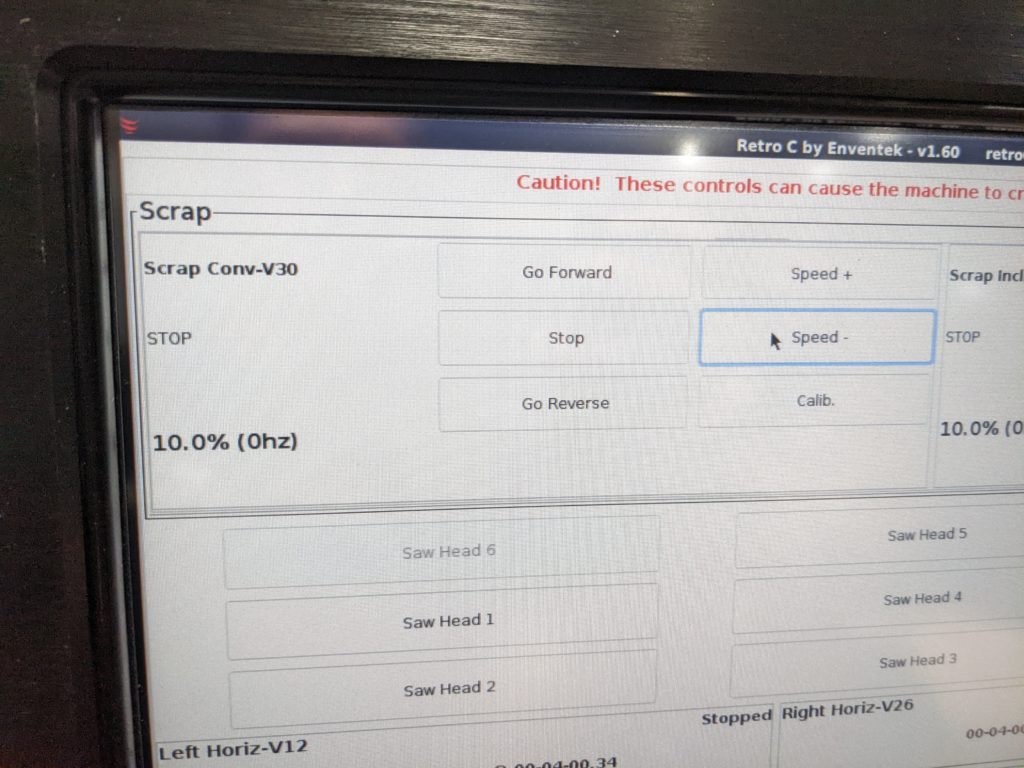

Step 4: Manually turn on the scrap conveyor and run it at very low speed (10%) and then gradually higher speed once you can verify that the belt is staying in the center. If the belt does not stay centered and moves to far to one side or the other adjust and repeat this step.

Step 5: Once you are happy with how the belt is tracking, tighten the locknuts back up and replace the chain guard.

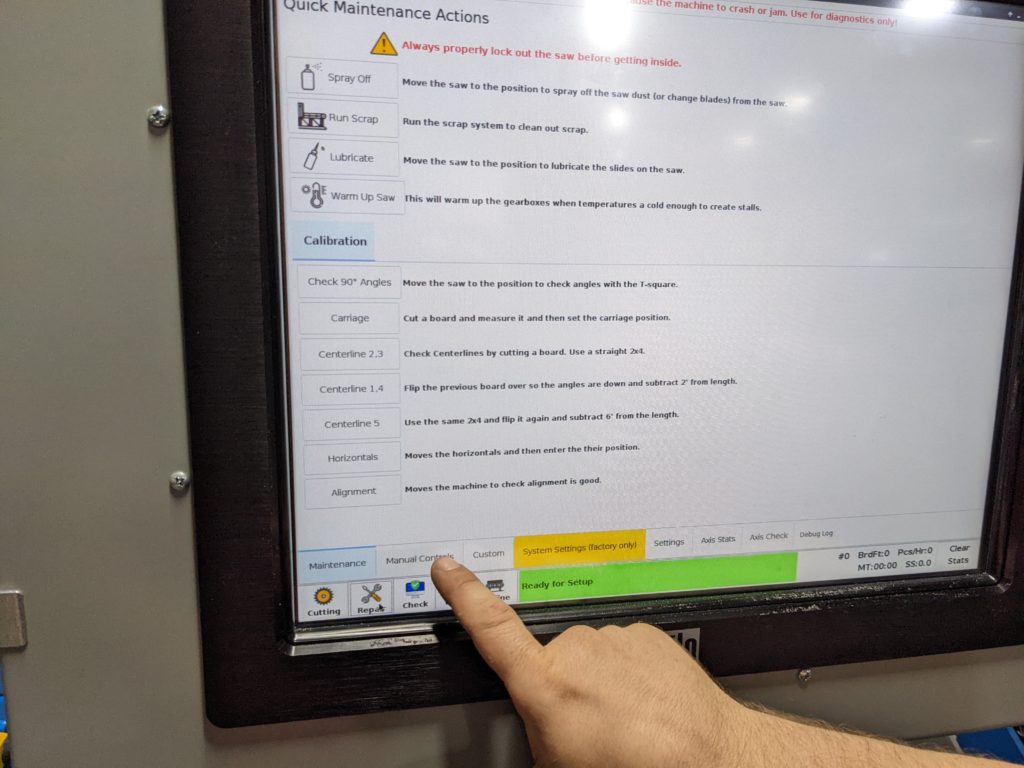

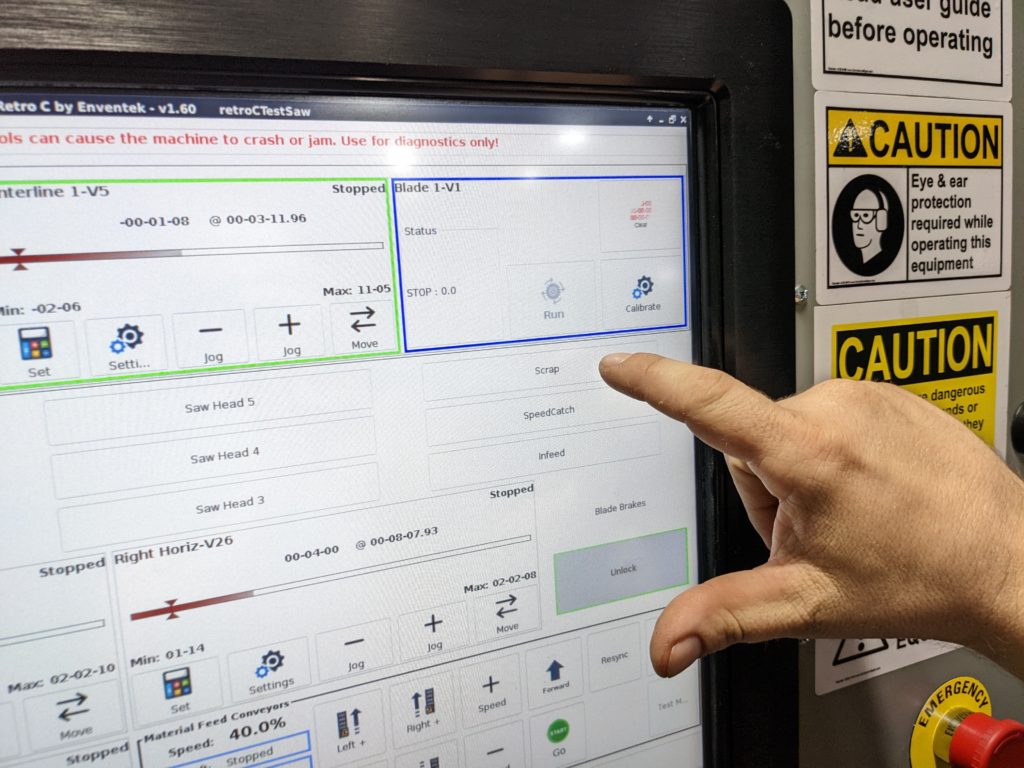

FYI: Steps to get to the Scrap Conveyor manual controls.