Search for answers or browse our knowledge base.

-

Retro C

-

-

- Articles coming soon

-

- How to Replace the Retro C's Computer

- Configuring the Touchscreen Computer's "Power-On"

- How to replace micro USB on the display computers

- How To: Transfer Files to the Retro C

- How to replace the USB hard drive on the touch screen computer

- New computer set bios power on

- Old computer set bios to power on

- TouchScreen Flip / Mirror Issue

-

-

-

- Stuck Angle or Centerline - How to Recover & Recalibrate

- Replacing an Angle Encoder

- Angle movements over run when going to position.

- Angle (Arch) Movements - Overview

- Angle Chains - Proper Chain Tension

- Diagnosing Unknown Noises Coming from Blade Motor

- Pivot Point Check

- Power or Wiring Troubleshooting for Angle Motors or VFDs

-

- Stuck Angle or Centerline - How to Recover & Recalibrate

- How To: Calibrate Centerline 1-5

- How To: Calibrate Centerline 1-5 (Advanced)

- Centerline (Vertical) Movements - Overview

- Replacing a Centerline Encoder

- Replacing a Centerline Gearbox

- Checking the Centerline Maximum & Minimum (Max & Min) Height Setting

- How to Tighten the Centerline Slides

- How To: Tension The Centerline Chains

-

-

-

- Common Retro C issues and solutions

- Countdown Timer / E-Stop Troubleshooting

- Scrap Belt or Scrap Incline VFD Disconnected: Troubleshooting

- Stuck Angle or Centerline - How to Recover & Recalibrate

- TouchScreen Flip / Mirror Issue

- Troubleshooting: Encoder Unplugged Error

- Troubleshooting: The Stationary or Carriage Side Horizontals Won't Move Anymore

-

-

Linear Pickline

-

Plant One Projection

-

SmartConveyor

-

Sticker Printer

RetroC – Saw Head Vibration Noises

If you have a head that makes a vibrating or humming noise there are typically 2 reasons

Reason #1 – The encoder guard plate might be vibrating steel on steel. The easiest way to check this is to temporarily put a piece of cardboard or paper in between the two pieces of steel and manually start the motor up. If the vibration noise you were hearing goes away you have found the problem.

Reason #2 – Once you have verified that the noise isn’t coming from a guard plate go through these steps. (For all of these steps we recommend that you take the blade off so it is easier to work in and around the brake).

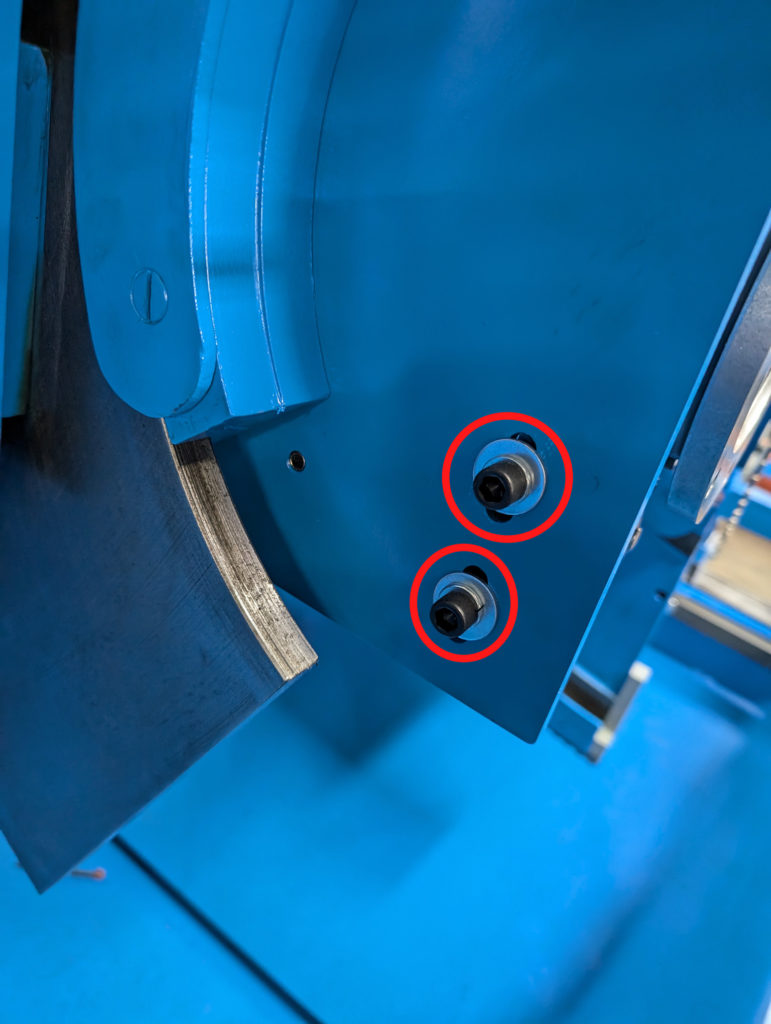

- Make sure that the small set screw (circled in red below) that tensions the brake caliper connecting pin is tight.

- Make sure that the spring is “springy” enough and able to push the left caliper back away from the hub enough. If not you can pull the spring out and stretch it or order another one from us.

Next, adjust the tension on the two calipers (L & R) so both touch the hub at the same time when engaged. For the left rotor the long bolt and set nut is how you adjust that (see image above). For the right one see the image below. Make sure both brake calipers are as close to the hub as they can be without touching and both are centered on the hub. I suggest you unlock the blade brakes so you can spin the hub freely while performing this check.

Lastly, on some of our newer saws we moved away from a welded blade brake support arm and we now have a little adjustment (on the “Y” axis”. Please make sure that these allan screws are tight.