Search for answers or browse our knowledge base.

-

Retro C

-

-

- Articles coming soon

-

- How to Replace the Retro C's Computer

- Configuring the Touchscreen Computer's "Power-On"

- How to replace micro USB on the display computers

- How To: Transfer Files to the Retro C

- How to replace the USB hard drive on the touch screen computer

- New computer set bios power on

- Old computer set bios to power on

- TouchScreen Flip / Mirror Issue

-

-

-

- Stuck Angle or Centerline - How to Recover & Recalibrate

- Replacing an Angle Encoder

- Angle movements over run when going to position.

- Angle (Arch) Movements - Overview

- Angle Chains - Proper Chain Tension

- Diagnosing Unknown Noises Coming from Blade Motor

- Pivot Point Check

- Power or Wiring Troubleshooting for Angle Motors or VFDs

-

- Stuck Angle or Centerline - How to Recover & Recalibrate

- How To: Calibrate Centerline 1-5

- How To: Calibrate Centerline 1-5 (Advanced)

- Centerline (Vertical) Movements - Overview

- Replacing a Centerline Encoder

- Replacing a Centerline Gearbox

- Checking the Centerline Maximum & Minimum (Max & Min) Height Setting

- How to Tighten the Centerline Slides

- How To: Tension The Centerline Chains

-

-

-

- Common Retro C issues and solutions

- Countdown Timer / E-Stop Troubleshooting

- Scrap Belt or Scrap Incline VFD Disconnected: Troubleshooting

- Stuck Angle or Centerline - How to Recover & Recalibrate

- TouchScreen Flip / Mirror Issue

- Troubleshooting: Encoder Unplugged Error

- Troubleshooting: The Stationary or Carriage Side Horizontals Won't Move Anymore

-

-

Linear Pickline

-

Plant One Projection

-

SmartConveyor

-

Sticker Printer

Replacing a Centerline Encoder

The centerline encoder is the counter that tracks the position of the vertical movement.

Warning: Before entering the saw make sure you have engaged the emergency stop with the key and take it with you as well. Always lock out, tag out the machine during maintenance in accordance with all local and/or company policies.

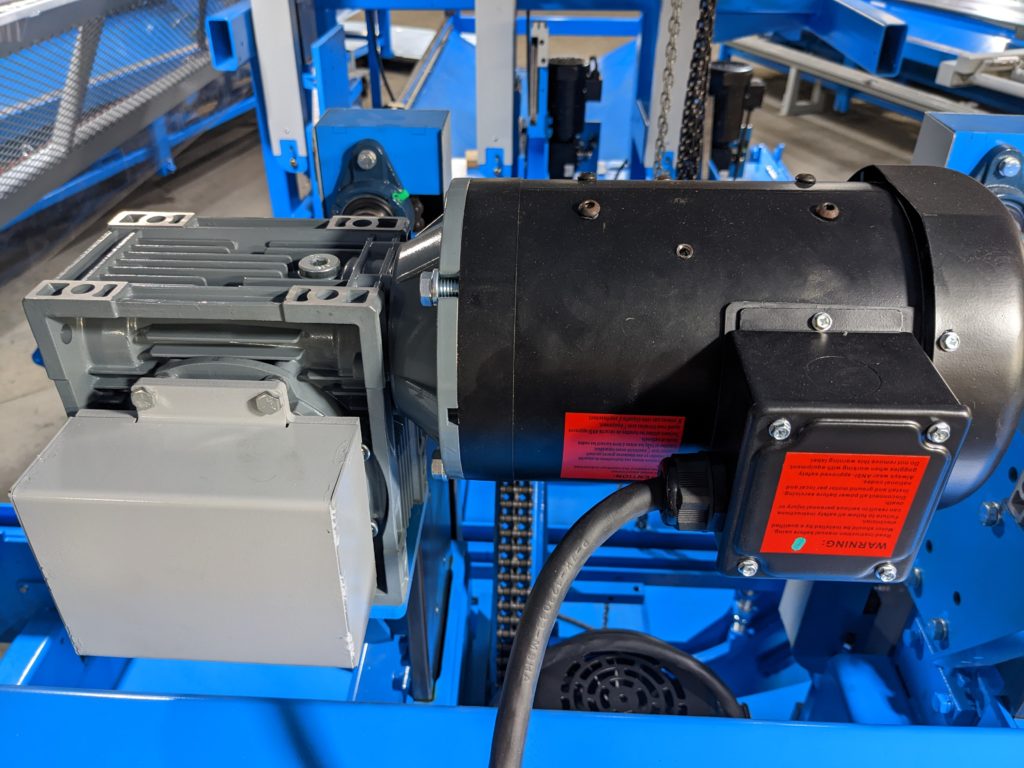

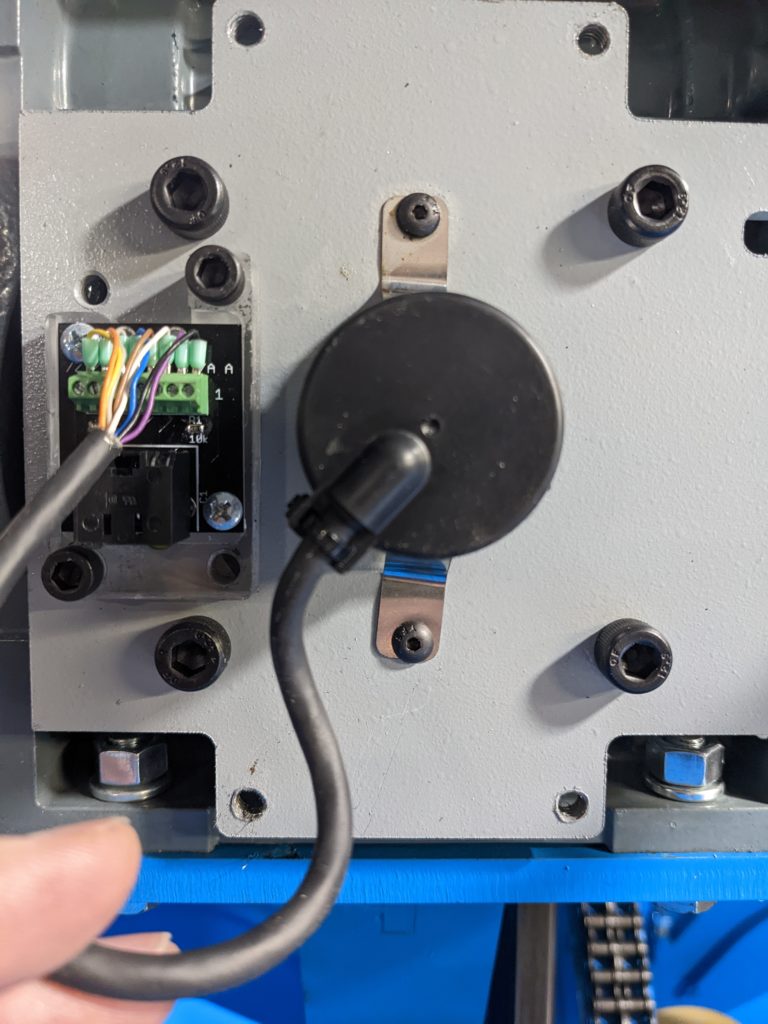

The centerline encoder is located either on the end of the shaft for the (older) Joyce actuator style or on the end of the shaft of the gearbox (newer style) behind a gray cover (shown below).

Remove the two screws holding the encoder in place and unplug the wire.

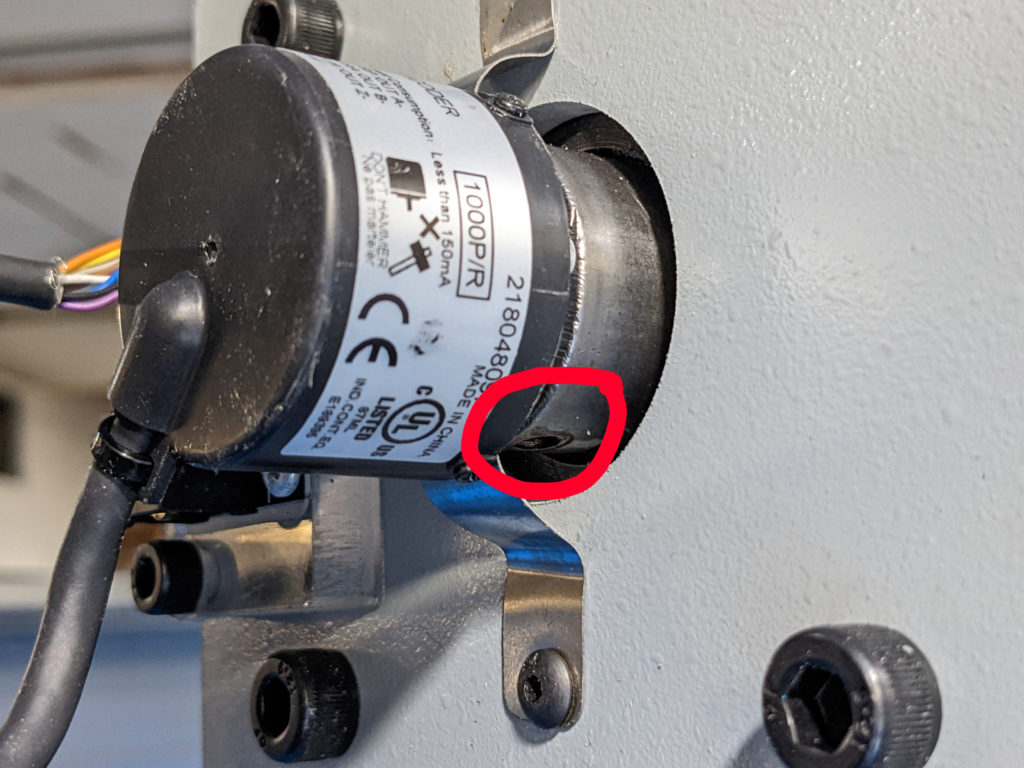

Loosen the set screw (set screw location is circled in red). And the encoder will slide off.

Remove the Encoder block.

Cut the new encoder to the length of the old encoder and wire it into the encoder block. Wiring Encoder Block

Remount encoder block and encoder on to the machine.

Secure the Set screw that holds the encoder.

Screw in the (2) 8-32 screws into the flanges on the encoder.

Mount the encoder block.

Add the encoder wire mount,

Test the encoder.

Re-Install all of the covers.