Search for answers or browse our knowledge base.

-

Retro C

-

-

- Articles coming soon

-

- How to Replace the Retro C's Computer

- Configuring the Touchscreen Computer's "Power-On"

- How to replace micro USB on the display computers

- How To: Transfer Files to the Retro C

- How to replace the USB hard drive on the touch screen computer

- New computer set bios power on

- Old computer set bios to power on

- TouchScreen Flip / Mirror Issue

-

-

-

- Stuck Angle or Centerline - How to Recover & Recalibrate

- Replacing an Angle Encoder

- Angle movements over run when going to position.

- Angle (Arch) Movements - Overview

- Angle Chains - Proper Chain Tension

- Diagnosing Unknown Noises Coming from Blade Motor

- Pivot Point Check

- Power or Wiring Troubleshooting for Angle Motors or VFDs

-

- Stuck Angle or Centerline - How to Recover & Recalibrate

- How To: Calibrate Centerline 1-5

- How To: Calibrate Centerline 1-5 (Advanced)

- Centerline (Vertical) Movements - Overview

- Replacing a Centerline Encoder

- Replacing a Centerline Gearbox

- Checking the Centerline Maximum & Minimum (Max & Min) Height Setting

- How to Tighten the Centerline Slides

- How To: Tension The Centerline Chains

-

-

-

- Common Retro C issues and solutions

- Countdown Timer / E-Stop Troubleshooting

- Scrap Belt or Scrap Incline VFD Disconnected: Troubleshooting

- Stuck Angle or Centerline - How to Recover & Recalibrate

- TouchScreen Flip / Mirror Issue

- Troubleshooting: Encoder Unplugged Error

- Troubleshooting: The Stationary or Carriage Side Horizontals Won't Move Anymore

-

-

Linear Pickline

-

Plant One Projection

-

SmartConveyor

-

Sticker Printer

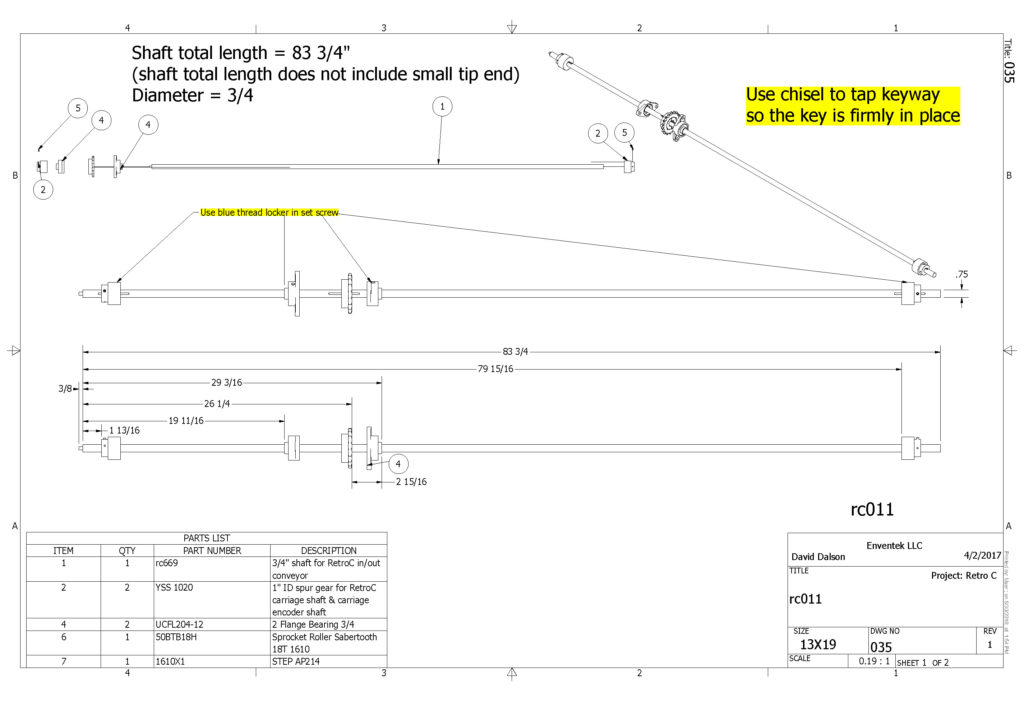

Assembling the Horizontal Conveyor Shaft

Retro C Conveyor Shaft Assembly Procedure

Step 1: shaft

- check shaft length according to sheet above

- check shaft diameter according to sheet above

Step 2: shaft clamp

- clamp shaft 10 inches from the right side in shaft clamp

Step 3: right end sprocket

A) insert right end sprocket from the right side of the shaft

B) Adjust right end sprocket according to dimensions on the sheet and tighten

Step 4: pillow block bearing 2

A) insert pillow block bearing 2 from left side of the shaft

B) Adjust pillow block bearing 2 according to dimensions on the sheet and tighten

Step 5: drive Sprocket

A) insert drive sprocket from left side of the shaft

B) Adjust drive sprocket according to dimensions on the sheet and tighten

Step 6: pillow block bearing 1

A) insert pillow block bearing 1 from left side of the shaft

B) Adjust pillow block bearing 1 according to dimensions on the sheet and tighten

Step 7: left end sprocket

A) insert left end sprocket from left side of the shaft

B) Adjust left end sprocket according to dimensions on the sheet and tighten