How Can We Help?

Search for answers or browse our knowledge base.

Retro C: Cleaning & Maintenance Schedule

Note: Certain conditions, including damp environments or certain types of wood (SYP), may require extra cleaning and lubrication, adjust as necessary.

Lubrication: Use a mixture of motor oil and kerosene (1:16) to clean out excessive resin buildup and lubricate. Very light lubricants and dry lubricants (graphite) should be used on all sliding metal surfaces as needed. Lubrication of the slides varies quite a bit depending on the type of wood being cut and the environmental conditions.

Daily

- Clean sawdust out of the saw.

- Most customers use compressed air at the start/end of their shift to clean up the sawdust

- Don’t forget these “other” locations:

- The material in feed conveyors “in and out”

- Energy Chain Track

- Lubricate slides, castings, and chains as needed (some people do this every day (in Texas for example) – Do this after compressed air cleaning.

- Use a pump sprayer with a kerosene and motor oil mixture: 10 parts kerosene to 1 part 30-weight motor oil

- An oil can is good for lubricating chains – but not slides. Use a Pump Spray for the metal slides.

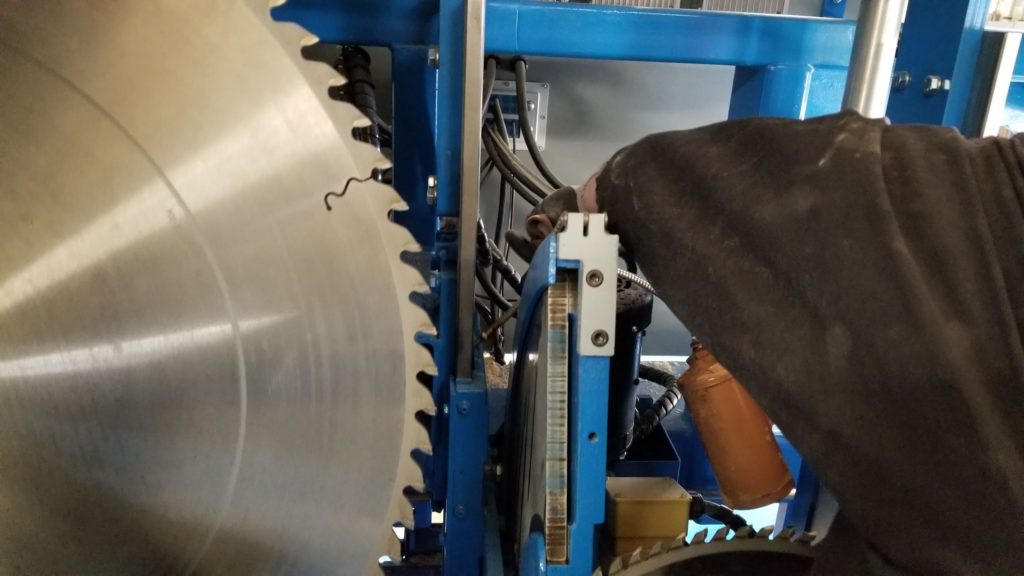

EXAMPLE OF WHAT NOT TO DO:

- SAW DUST WAS NOT BLOWN OFF PROPERLY BEFORE LUBRICATING, AS SEEN BY THE STREAKING AND DRIPPING PATTERN ON THE METAL SLIDES.

- A PUMP SPRAY WAS NOT USED FOR THE FLAT SURFACES.

- For the Carriage V-track, the use of straight kerosene is OK.

- Clean any pitch from the saw blades and the moving components as needed.

- Check the blade brakes to make sure they are working.

- Check the E-Stop system.

Weekly

- Check air filter/oiler

- If you need to add additional oil we recommend “CLIsyntec Air Tool Lubricant – Premium Industrial Pneumatic Tool Oil”

- Check for and fix any air leaks.

- Check blades for sharpness. (Change if needed)

- Inspect angles and centerlines for build-up of debris.

Monthly

- Check integrated actuator worm gear with 2-3 pumps of grease (Mobilegrease XHP 461). Stop if grease comes out of the seal near the encoder. Do not over-lubricate. (Older Joyce Actuator version) Not required on new chain centerlines.

- Inspect blade hubs for tightness. Note: Do not remove or try to take apart.

- Check saw squareness and confirm it is correct realign as needed.

- Check the tightness of the material feed chains

- Check Infeed Conveyor chain tightness

Yearly

- blade motors. Blades 1,2,3,4 (5500 hrs. operation) Blade 5 (9500 hrs. operation) 1-2 pumps. Clean the grease gun and fittings before greasing. Use Polyrex EM or compatible grease. Do not mix grease types. Do not over-lubricate.

- Check the tightness of the carriage encoder, spur gears, and motor torque limiter.

- Check all encoders for damage and connection to their shafts.

- Check for rust in the angle and centerline movements and clean as needed.

- Fully clean out the gear rack.

- Vacuum out the electrical panels to prevent any sawdust build-up. (Do not blow air into them as it will push debris into the electronics)

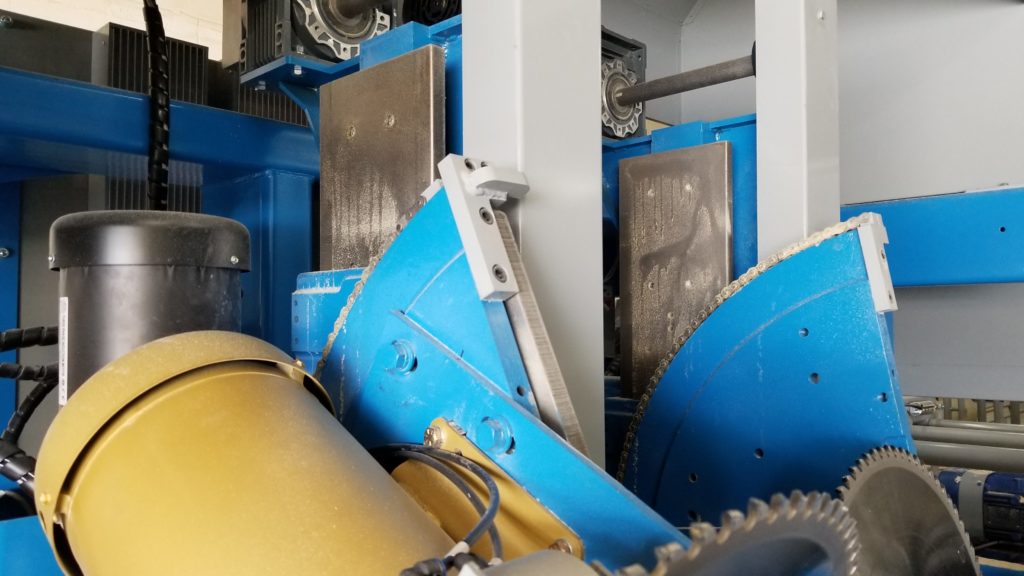

Saw Blades and Hubs

- Saw blades should be tightened between 18-20 ft lbs. Recheck hub tightness on a Monthly schedule. Never remove a saw hub.

- Hubs with bushing size #2517 should be tightened to 35.8-39.4 ft lbs. (most common type)

- Hubs with bushing size #1215 should be tightened to 14.6-16 ft lbs (Old style)