Search for answers or browse our knowledge base.

Sticker Printer Overview

The Retro C’s Sticker Printer was created to eliminate the need for writing information on lumber manually. This printer integrates with the saw’s cut list to offer an efficient labeling solution for lumber. It can be mounted either on the front or the back of the saw. Most customers prefer the front mount option because the look-ahead feature allows the saw operator to take the sticker and simultaneously check the lumber. This method also helps keep track of the operator’s progress within the batch as the lumber moves away from them.

The front mount option delivers high-quality 3×2 stickers “just in time.” The printer features an automatic take-up reel for the excess backing paper, which it winds back into the bottom of the machine for you. It prints one sticker at a time, waiting for you to remove the sticker before proceeding to the next one in the list.

The back mount option prints the appropriate labels as the board is set up on the saw, allowing the saw catcher to apply the stickers. This approach works well with manual boards but lacks the benefits of the look-ahead feature provided by the front mount.

One of the first questions people often ask is about the cost of replacement ink cartridges. The answer is $0.00 because this unit does not use ink at all. Instead, it employs a “Direct Thermal” printhead that uses chemically treated, heat-sensitive media, which blackens when it passes under the thermal printhead. This means that you only need the right type of labels. The second question is usually about the cost of these labels, which are approximately $0.01 each.

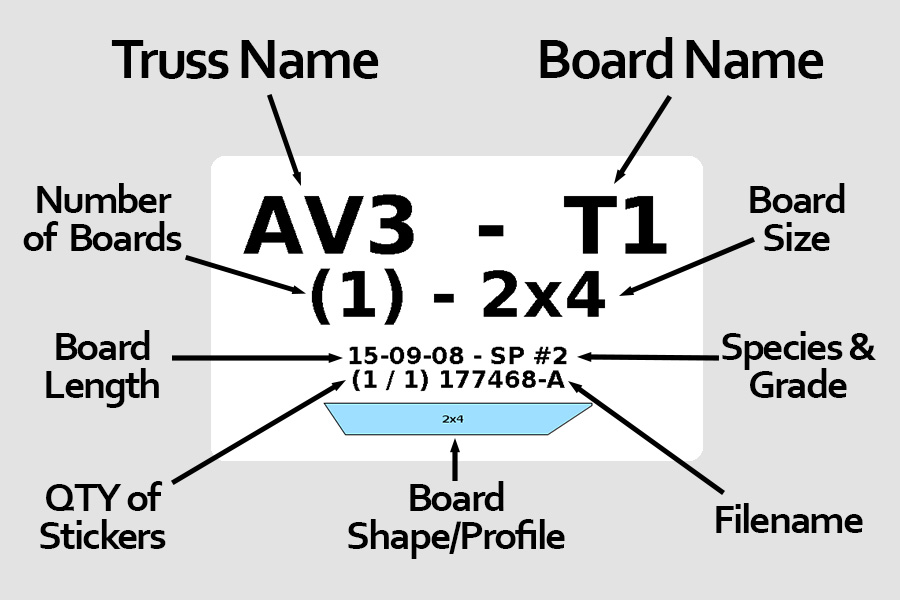

Sticker Example

This image explains what information is printed onto each sticker. At this time, the arrangement of the information and what is displayed can NOT be changed by the end user.

Mounting

The sticker printer can be placed on the sawyer’s side of the saw or it can be placed on the catcher’s side. Most customers have opted to put it on the sawyer’s side. The printer has a support arm that holds the printer above the table/wood. There is a dust cover that is placed over it during operation.

Sticker Printer Peel-Off Operation

This example shows you how the printer will automatically peel off the backing from the sticker and then wait for you to remove it before printing another sticker.

In this video the Sawyer is putting stickers on every board

Quantity Options

You can easily select between printing 1 sticker per setup/cut

- One sticker is printed for every board.

- One sticker is printed for every saw setup – (The sticker is placed on the first or last board)

- NOTE: If the software combines two identical boards that have different names into one setup you will get an additional sticker.

- Two stickers per saw setup – (The sticker would be placed on the first and last board)

- NOTE: If the software combines two identical boards that have different names into one setup you will get two additional stickers.

- “Every Other” – One sticker is printed for every other board.