Search for answers or browse our knowledge base.

-

Retro C

-

-

- Articles coming soon

-

- How to Replace the Retro C's Computer

- Configuring the Touchscreen Computer's "Power-On"

- How to replace micro USB on the display computers

- How To: Transfer Files to the Retro C

- How to replace the USB hard drive on the touch screen computer

- New computer set bios power on

- Old computer set bios to power on

- TouchScreen Flip / Mirror Issue

-

-

-

- Stuck Angle or Centerline - How to Recover & Recalibrate

- Replacing an Angle Encoder

- Angle movements over run when going to position.

- Angle (Arch) Movements - Overview

- Angle Chains - Proper Chain Tension

- Diagnosing Unknown Noises Coming from Blade Motor

- Pivot Point Check

- Power or Wiring Troubleshooting for Angle Motors or VFDs

-

- Stuck Angle or Centerline - How to Recover & Recalibrate

- How To: Calibrate Centerline 1-5

- How To: Calibrate Centerline 1-5 (Advanced)

- Centerline (Vertical) Movements - Overview

- Replacing a Centerline Encoder

- Replacing a Centerline Gearbox

- Checking the Centerline Maximum & Minimum (Max & Min) Height Setting

- How to Tighten the Centerline Slides

- How To: Tension The Centerline Chains

-

-

-

- Common Retro C issues and solutions

- Countdown Timer / E-Stop Troubleshooting

- Scrap Belt or Scrap Incline VFD Disconnected: Troubleshooting

- Stuck Angle or Centerline - How to Recover & Recalibrate

- TouchScreen Flip / Mirror Issue

- Troubleshooting: Encoder Unplugged Error

- Troubleshooting: The Stationary or Carriage Side Horizontals Won't Move Anymore

-

-

Linear Pickline

-

Plant One Projection

-

SmartConveyor

-

Sticker Printer

Foot Pedal

The foot pedal plays a crucial role in operating the SmartConveyor or the Pickline, allowing users to keep their hands free while moving lumber forward.

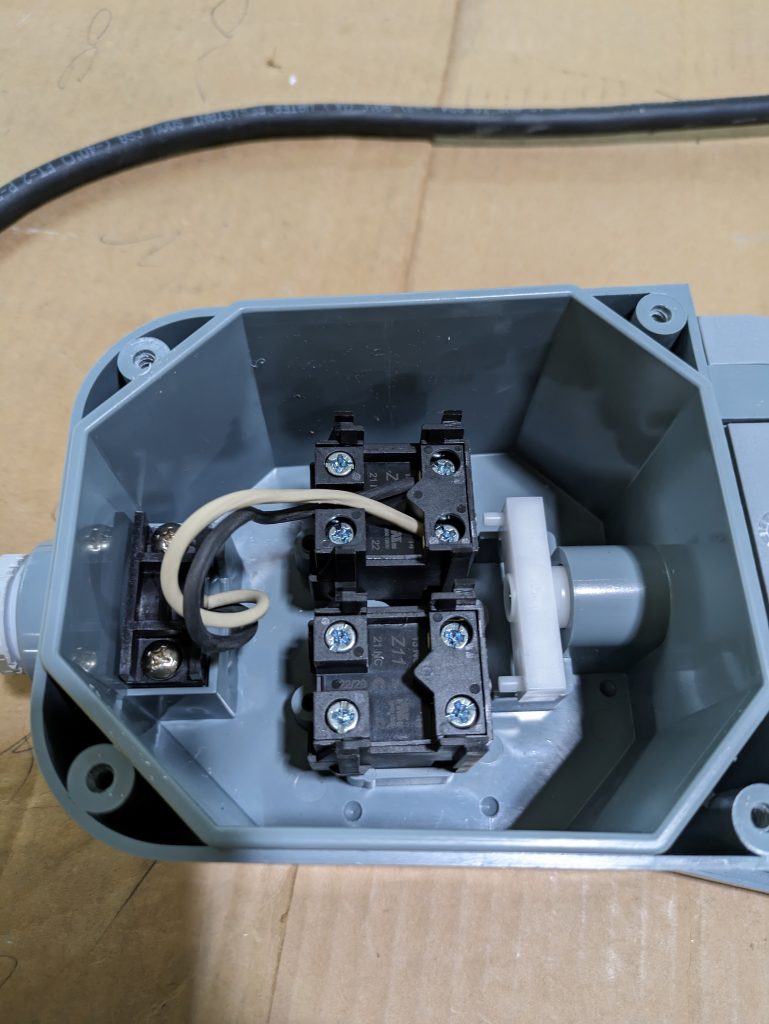

The pedal functions by closing a snap-action contact, as shown in the image above.

A single wire is responsible for running the foot pedal. In the photo, you can observe a black and white wire that, when connected together, signals the conveyor to move.

However, if the snap-action contact becomes stuck or breaks, it can lead to three potential issues:

- The conveyor fails to move when the foot pedal is pressed.

- The conveyor moves continuously even when the foot pedal is not pressed.

- The conveyor exhibits intermittent functionality.

It is important to note that in some Variable Frequency Drives (VFDs), if the foot pedal becomes stuck in the “on” position, it can cause unusual behavior. The pedal may not function as intended and may also confuse the computerized controls. For instance, if the computer instructs the conveyor to move backward by 12 inches, it may initially move backward but then start moving forward until the computer sends a command to turn it off, at which point it will stop.

The same issue can occur when moving forward. If the computer commands the conveyor to move forward by 12 inches, it may continue moving forward beyond 12 inches until the computer sends a stop command.

Below is a photo showing the contact block and potential obstructions that can cause the foot pedal to function poorly when stuck in the “on” position:

To address this issue, the contact block can be removed by pushing out the outside black clips and pulling it out. This will allow testing of the contact’s spring return.

It is recommended to check both the front and rear pedal terminals for any faulty snap-action contacts. Both pedals have an extra contact that can be swapped if needed until a replacement is obtained.

By following these steps, you can troubleshoot and resolve issues related to the foot pedals, ensuring proper functionality of the conveyor system.