Read More

Recalibrating the touchscreen on your Retro C is really easy to do and can be completed in less than 5 minutes. If you find that when you touch screen the cursor is off the steps outlined here can help tremendously.

Read More

This article will explain how to replace the wire and air hoses that run in the energy chain above the rear guard of the Retro C.

Read More

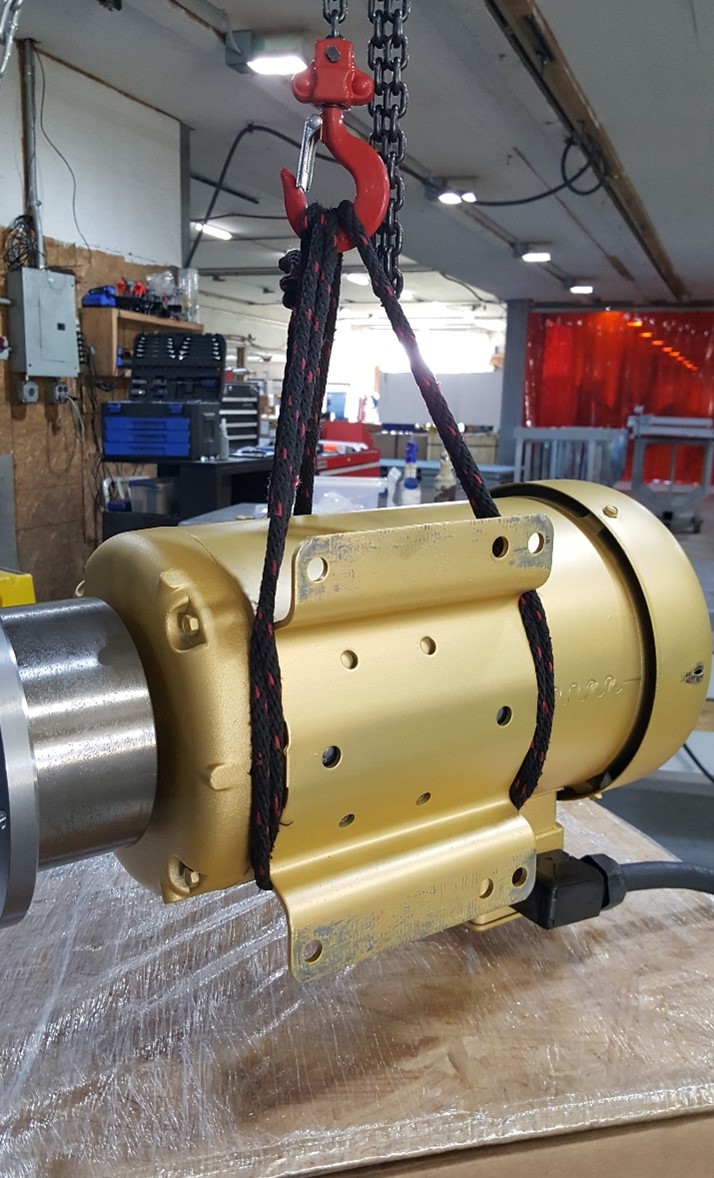

To replace a blade motor there are 9 steps

Power down the entire saw

Remove the saw blade

Unwire the (2) airlines and unwire the power cables

Remove the brake assembly

Using a hoist or forklift as a hoist remove the old blade motor

Attach the new blade motor

Re-attach the brake assembly

Re-wire the power cables and replace the (2) airlines

Attach the saw blade

Read More

The centerline encoder is the counter that tracks the position of the vertical movement. The centerline encoder is located either on the end of the shaft for the (older) Joyce actuator style or on the end of the shaft of the gearbox (newer style) behind a gray cover.

Read More

Replacing an Encoder is easy and should only take approximately 10-15 min for one person to complete. This article will show you how.

Read More

The encoders work to synchronize the two sides of the Retro C. If the saw loses synchronization or stalls it could be something mechanical, it may be that one of the encoders is starting to fail or it could be the connection of the encoder to the motor has broken. This article will teach you have to replace the encoder.

Read More

To replace the blade the steps are basically identical for all the blades. Reattach the blade to the saw with 3 screws (Blades 1,2,3,4). Blade number 5 gets (6) screws. Make sure the blade is attached with the teeth cutting toward the front of the saw (where the operator is standing). Put 3 screws into the three holes that are countersunk. The screw heads will NOT stick up past the plane of the blade if the correct 3 holes are chosen.

Read More