The Retro C is equipped with sensors that are constantly detecting the position of the lumber as it is loaded onto the material feed arms. As lumber passes by the sensors they measure the position of the board on each side to make sure that the board is not cross up.

Read More

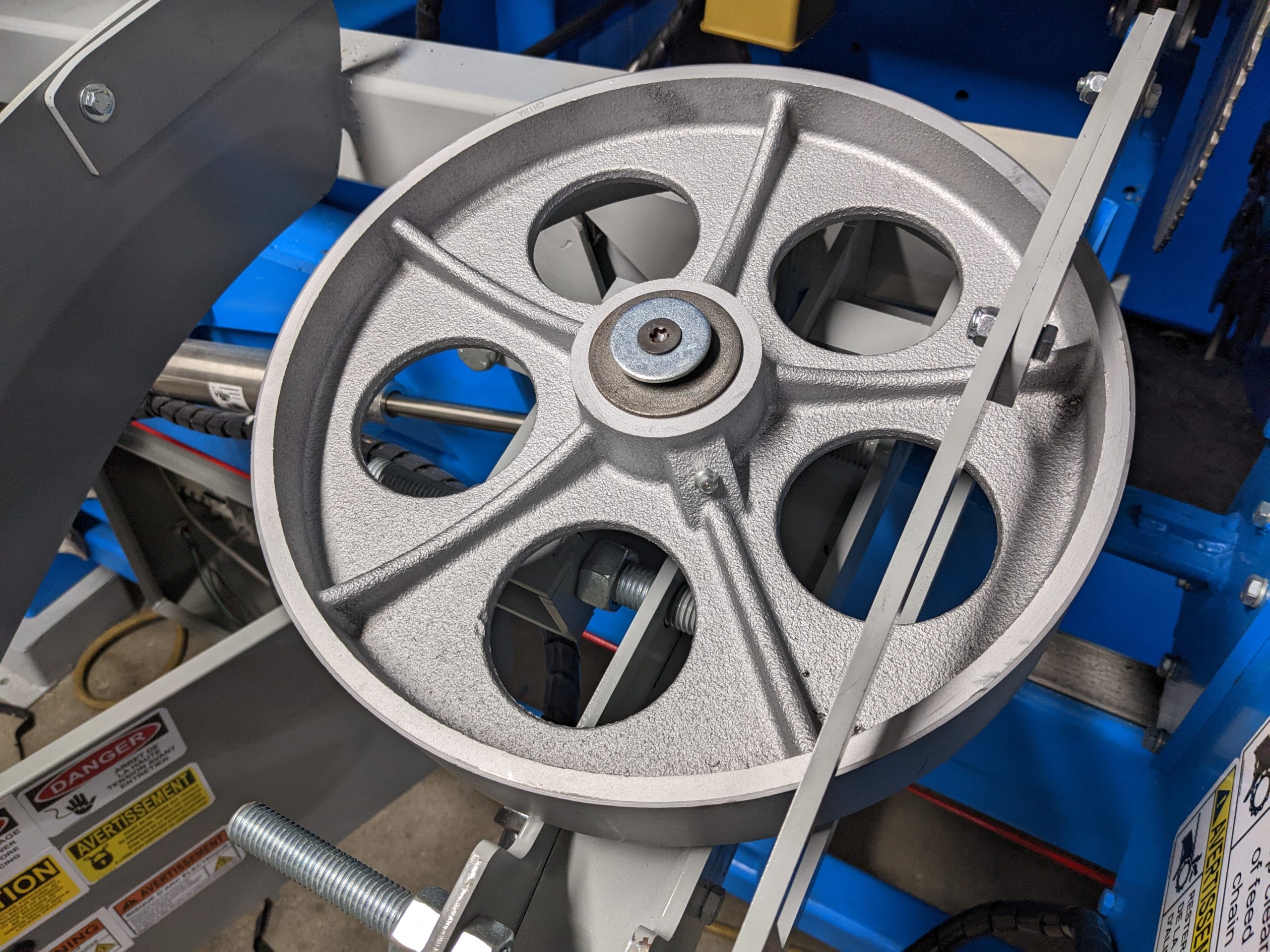

The lumber guide wheel is the final point of adjustment for the lumber before it is cut. The guide wheels job is to position the lumber so that it is inline with saw blade 1 and 2. If you find that the lumber isn't being cut at all (the wheel is pushing the lumber too far to the right or isn't pushing it in far enough and is consistently cutting length off of the lumber when it is a doing a standard 90 degree cut adjusting the wheel position can help.

Read More

The Material feed system is the conveyors that move the material through the saw. They have the custom 120 chains which support the material. They are synchronized by software so that there is not a mechanical connection between one side and the other of the machine.

From time to time the material feed conveyors need to be homed in order to correct the alignment.

Read More

Loss of synchronization between the left and right material feed chains can occur when there is a disproportional amount of load on the side or the other.

Read More