Retro C

The Component Saw System Process developed for you!

The Retro C is the most productive and cost-effective component saw in the truss industry. This auto-feeding component saw can cut “truss-by-truss” easily outperforming any linear saw. Consistent and rapid production is made possible by our unique automatic feeding system and user-friendly automation. Enventek works to provide solutions to the needs of the industry.

The Retro C is a fully automated component saw that has been completely rebuilt from a Mitek 1000, 2000, 3000, 4000, EasySet or Cyber A/T component saw frame. Enventek’s complete overhaul extends the life of the frame and more importantly, improves it beyond the original capabilities. The Retro C allows the operator to cut over 100+ pieces per minute giving this saw a very competitive edge on the market.

This saw is specifically designed for speed, accuracy and safety. The innovative automatic feed system allows Retro C operators to operate the system from the stationary side of the saw further distancing them from blades and the movements of the carriage during setups and operation.

New in 2022 Enventek is offering customers the ability to upgrade to our High Density (HD) saw system that enables even more speed and throughput. With our HD saw system you will have the ability to cut over 200 boards a minute enabling never-before-seen levels of throughput!

Retro C is the component saw designed with you in mind.

When we designed the Retro C we assessed what was already available in the industry and then we created a component saw that was designed to meet the specific needs of a truss plant. The Retro C is fast and reliable. It outperforms on cuts per minute while remaining very competitively priced. The synchronization between the saw and the infeed conveyor creates a more productive process. The automatic calculation of feeds and speeds takes the guesswork out of what speed to cut lumber. All of this was designed with you and your plant in mind.

- Faster speed & more board throughput

- Less down time & more production

- Less maintenance & fewer repair costs

- Intuitive user interface

- Safest component saw on the market

- Best pricing

Call For A Free Quote:

(269) 815-4150

Why Choose the RETRO C?

Built for Speed

The Retro C can cut over 100 pieces per minute with an average setup time of fewer than 9 seconds. It has a 30-second cycle time on a single 2×4 board (time from setup to setup with a board passing through the saw). New for 2022 is the option to upgrade to our high-density dogs which doubles the maximum cut speed to over 200 pieces per minute!

Safety First

Unlike many other saws, Retro C is operated from the stationary side of the saw rather than the carriage side. This keeps the operator out of the way of saw movements during setups. Auto-feed from the Retro C from our SmartConveyor allows the operator to run the saw hands-free which further increases safety.

Less Maintenance

Due to innovative engineering, we have been able to significantly reduce the number of moving parts and thus reducing the overall cost of the saw. An added bonus is that fewer moving parts mean less maintenance and upkeep costs, not to mention less training for your employees!

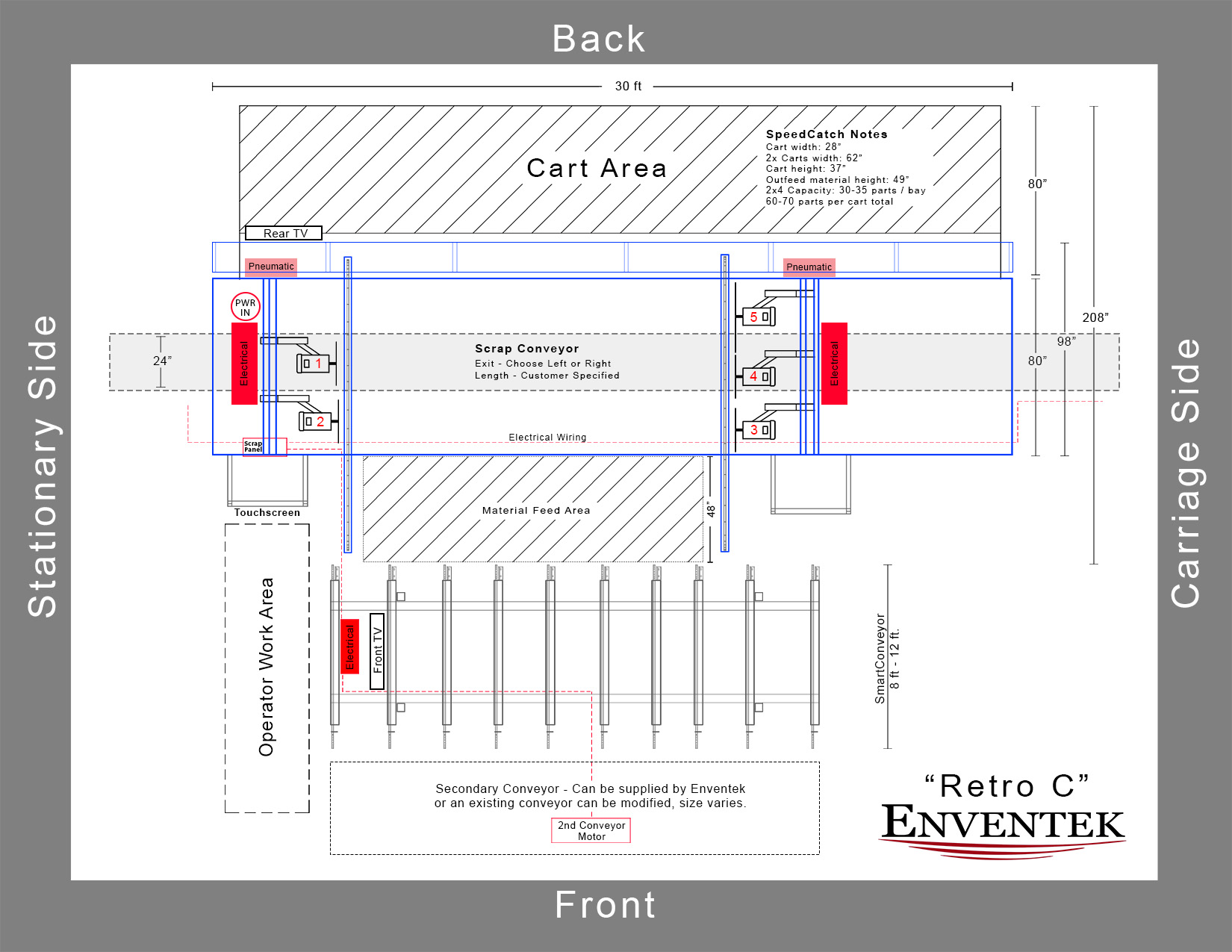

Retro C – Footprint

Videos

The Fastest Component Saw

The Retro C can cut up to 200 pieces of lumber per minute with our optional HD upgrade. It has a low 30-second maximum cycle time. This low cycle time makes it ideal for truss plants that frequently have low part runs as well as those that regularly run custom jobs.

Less Maintenance

The Retro C has a complete mechanical & electrical replacement from the original saw as well as a reduced number of moving parts. This reduces maintenance time and costs. Newer technology has led to a far simpler design that is easier to troubleshoot.

Safety First

The Retro C is operated from the stationary side of the saw keeping the operator out of the way of the saw during movements and setup. Because the “dogs” do the work of loading and feeding the lumber, operators stay further away from the blades. With SmartConveyor the operator is able to run the saw hands-free creating a safer work environment.

F.A.Q.

We know that a purchase like this is a big deal. We are here to answer any of your questions to help you feel comfortable with our products. Feel free to ask us any questions about the Retro C.

Why do you sell it with the infeed conveyor?

In order to provide the best experience for our customers, we provide the conveyor in front of the saw in sizes ranging from 8′ to 12′. By utilizing our SmartConveyor system, Retro C gains the ability to feed at speeds that can’t be achieved by other saws claiming to have an automatic mode.

What is automatic mode?

Automatic mode is where the saw sets up by itself and feeds the lumber automatically into the saw. When the correct quantity is loaded automatically by the infeed conveyor the saw will complete the run, set up for the next part, and continue without any user intervention. If you can keep the right quantity and sizes of lumber on the infeed conveyor the saw will run without user intervention indefinitely. Automatic mode enables unprecedented new levels of throughput and is revolutionizing the way our industry views component saws.

How fast is the Retro C?

There are two ways to measure the speed of the time. The best way to judge the speed of a saw is in cycle time. Cycle time is the time it takes for lumber to get cut, feed through the saw, and set up again. The Retro C can cut a 2×4 and set up for the next one in under 25 seconds. That means that in less than 60 seconds two different boards with different cuts and lengths can be processed through the saw.

The other way to measure speed is to measure raw throughput. Assuming you only had 1 setup and wanted to cut all 100 2×4’s the same way, the Retro C can easily cut all 100 in less than 1 minute. We have multiple customers who replace 2 or 3 saws with a single Retro C due to it’s speed.

New for 2022 we are offering all new customers the ability to upgrade to our High Density (HD) system that enables even more speed and throughput. With our HD saw system you will have the ability to cut up to 200 boards a minute allowing unseen levels of throughput!

Who sets the speed of the machine?

Feed speeds are calculated by the software based on the length of the cut, blade motor recovery times, the angle of cut, and lumber loading. Speeds are then set on the machine as a percentage of what the user can cut. In automatic mode, users can override the speed to 20% faster than the calculated max speed. In manual mode, the saw can run at a max speed of over 100 boards per minute.