Checking the Material Feed Arm and Carriage Alignment

Checking the saw alignment, while not difficult, needs to be done in the correct order to realign.

If the carriage moves during the cutting process it means one of two things. Either the Carriage air brake is not holding or the material feed conveyors are not parallel to each other

There are THREE possible sections that can & have been known to get out of alignment.

- Stationary Side Material feed arm (front/back) could be out of alignment if (A ≠ B) measurements are not equal.

- The Carriage itself could be twisted. Example: (A = B) and (E = F) but (C ≠ D) then the carriage is out of alignment.

- Carriage Side Material feed arms out of alignment if (front/back) E ≠ F.

NOTE: Always measure and align LEFT to Right

NOTE: print off this PDF file.

After you have printed this off please fill in the correct values for A,B,C,D,E,F. It will likely be helpful to look below at some of the pictures to get an idea of exactly where to measure to and from for each location.

If everything is aligned properly A = B, C = D, E = F if this is not the case then we need to realign one or more of the arms or the carriage itself.

Here are the Steps:

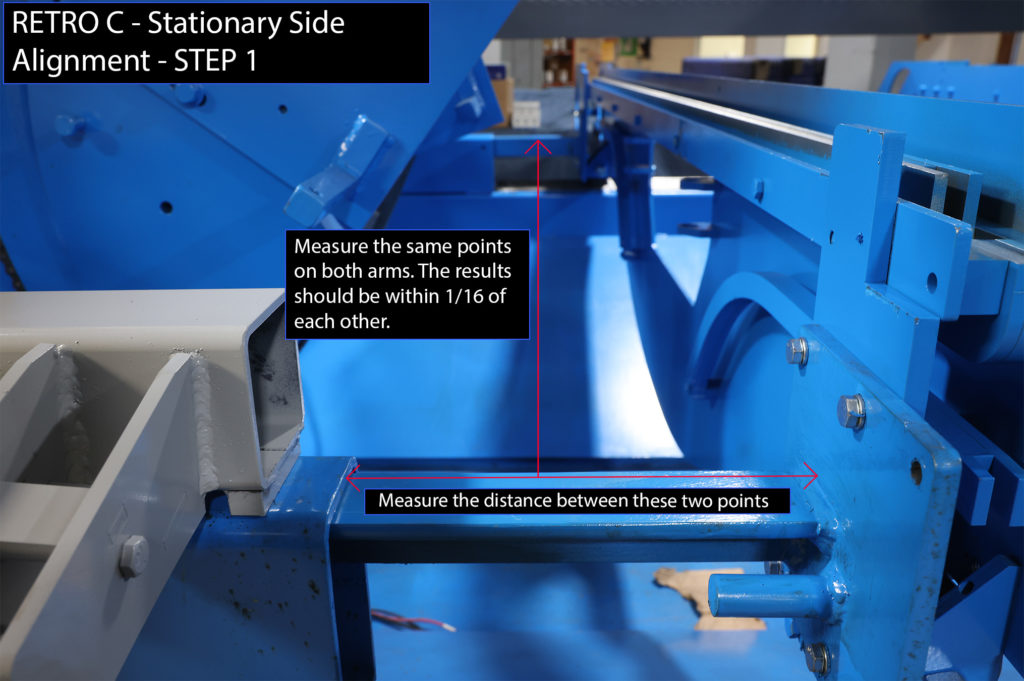

Step 1

You will be measuring to make sure that the distance between the frame of the saw and the conveyors arm is the identical on BOTH ENDS (with 1/16th).

If the distance between the left frame tube on the stationary side of the saw and the bracket for the material feed conveyor are the same proceed to step 2. If the measurements are off by more than 1/16th proceed to step #4

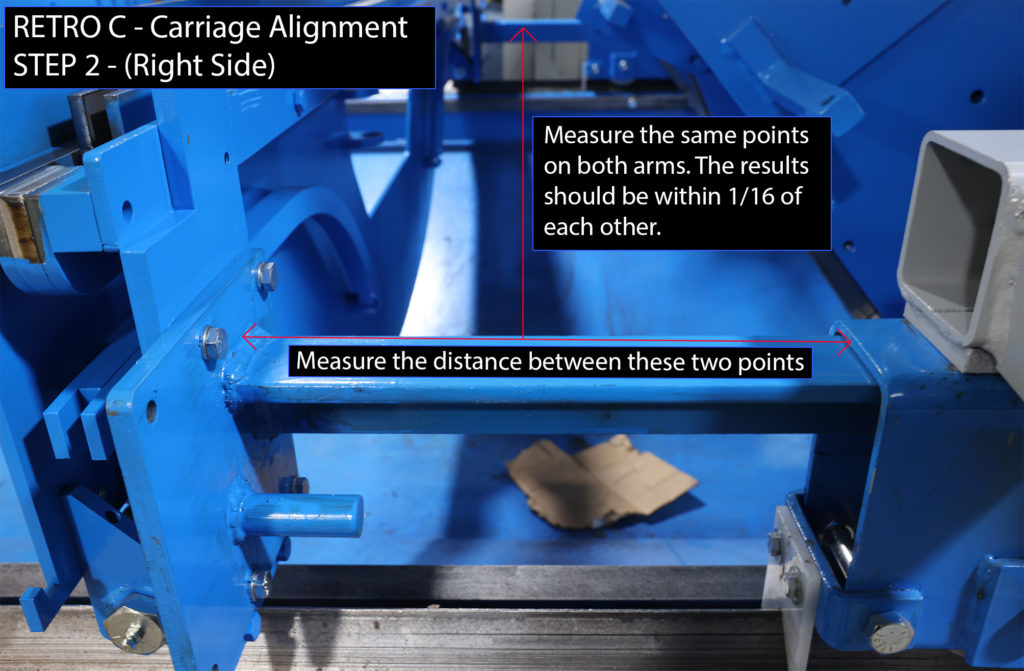

STEP 2

Measure the distance between the Carriage side frame tube to the Material feed bracket.

If the distance between the Material feed bracket and the frame is the same proceed to step 3. If the measurements are off by more than 1/16th proceed to step #4

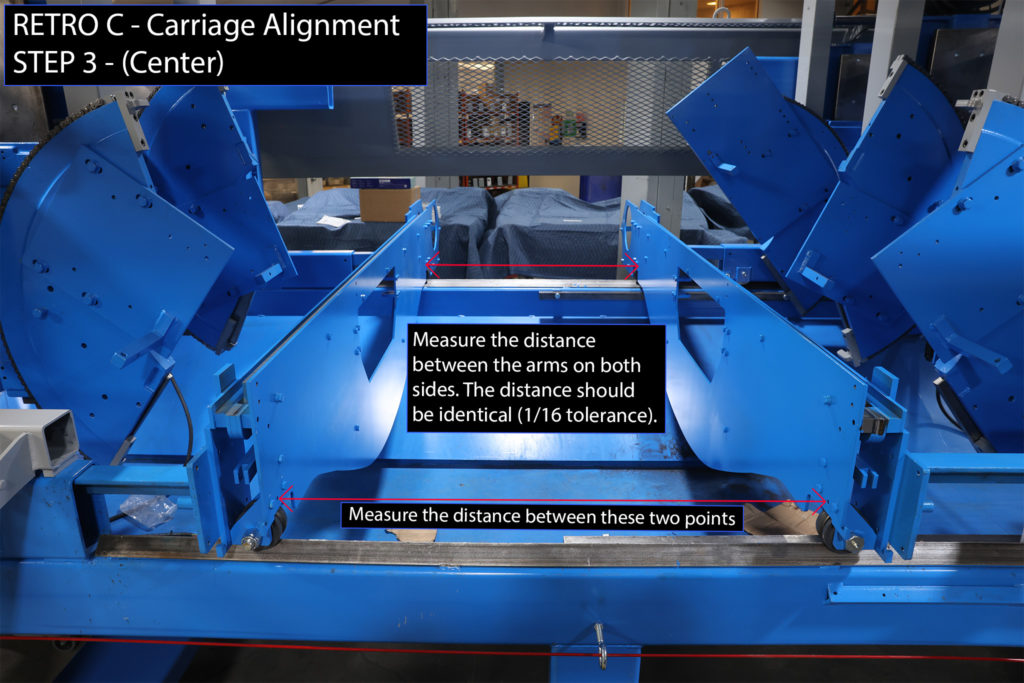

Step 3

Measure the distance between the two carriage arms.

If the distance between the two carriage arms is same skip ahead to Step 5. If the measurements are off by more than 1/16th on Step 1, 2, or 3 proceed to Step 4.

Step 4 – Re-align the arms/carriage

NOTE: If you are having issues getting accurate measurements for the Carriage. You can measure the carriage alignment by moving the carriage to 20′ and measure to the end of the frame. Should measure about 2″.